Bridging bold ideas and dependable delivery.

Ambitious design teams push materials and geometries to the edge. Procurement teams need supply chain reliability, documentation, and compliance. Multiscale Systems delivers both.

By combining wire-laser directed energy deposition (DED) with precision CNC machining, we create fully-dense, inspection-ready components in alloys that withstand heat, wear, and corrosion. Our hybrid manufacturing process reduces lead times, simplifies supply chains, and produces data packages that stand up in nuclear QA reviews.

Capability Pillars

Engineering Integrity

Complex geometries, dissimilar material transitions, and optimized alloys, manufactured for durability, repairability, and high-value performance.

Procurement Confidence

ISO 9001 / AS9100 certified, CMMC Level 2, ITAR-ready. Every order includes full traveler history, traceable materials, and inspection records.

Program Alignment

A single accountable supplier for design feasibility, first article qualification, and production release. Predictable schedules, auditable results.

Vertical Integration

Engineering and manufacturing under one roof.

Our co-located facility in central Massachusetts efficiently delivers combined design, engineering, and manufacturing for a seamless and simplified procurement process.

Manufacturing

Additive flexibility. Subtractive precision. One system.

Consistent, high-tolerance results with single-setup additive and subtractive manufacturing.

Hybrid Manufacturing

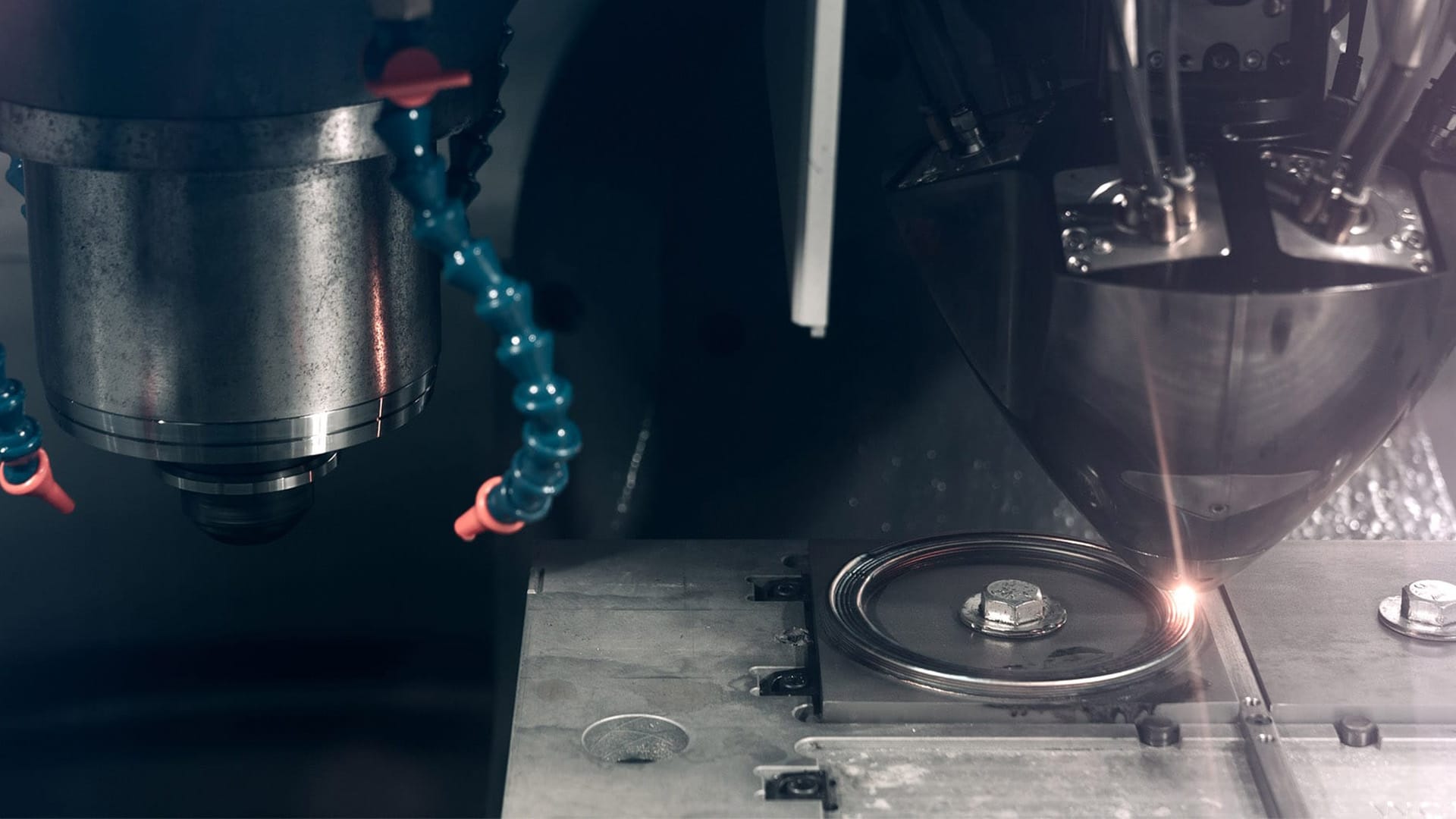

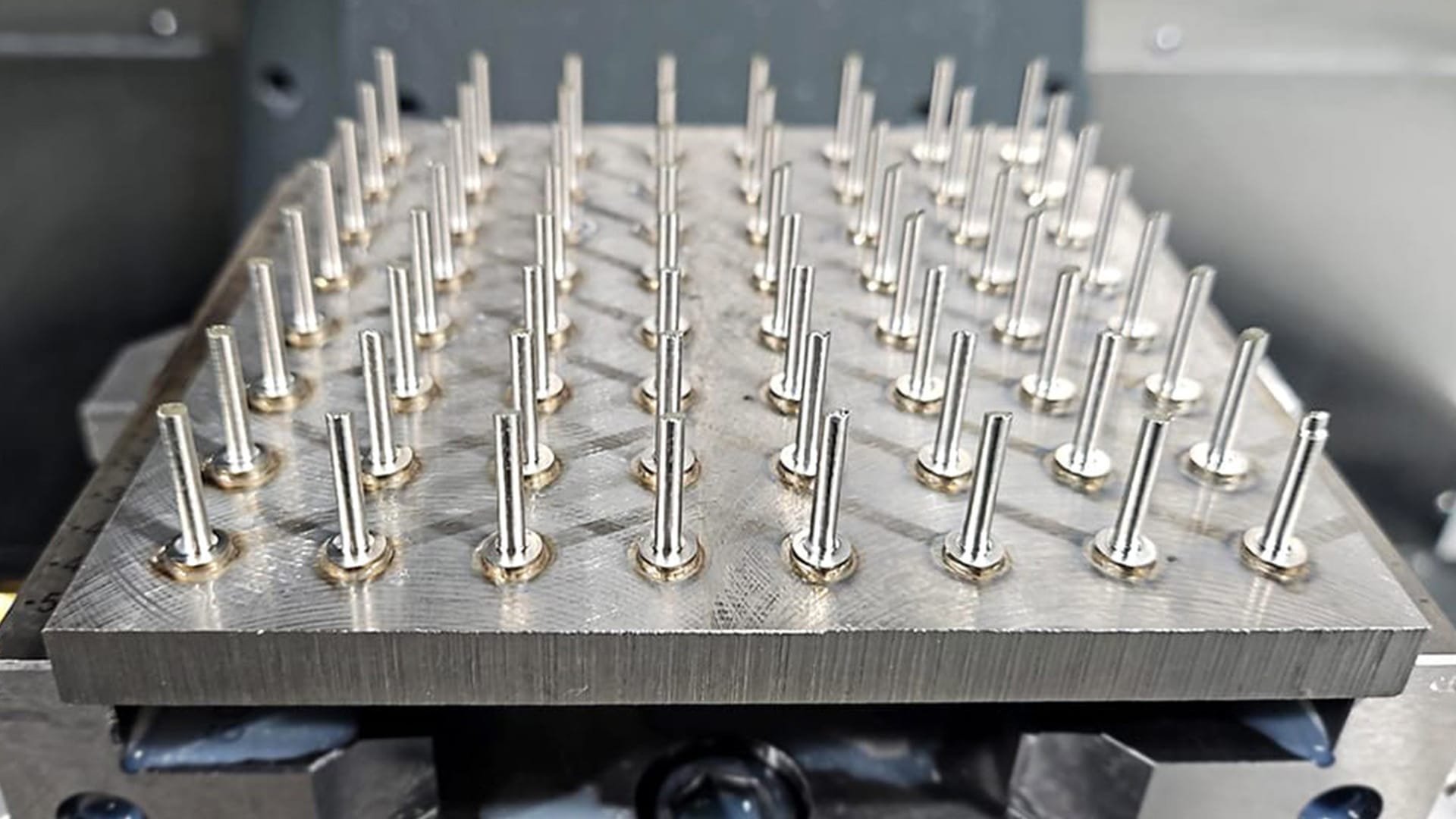

Multiscale’s hybrid systems use wire-laser DED as the additive method, chosen for its advantages over powder-based methods. Lasers melt wire feedstock, building up layers to create a preform. Subtraction is handled by an integrated 3- or 5-axis CNC for precision shaping and finishing.

Hybrid processes enable near-net preform builds directly in the CNC, replacing the long lead times of forgings and the defect risks of castings. Single-setup machining streamlines quality control while attaining precision parts.

Efficiency

Fully dense, void-free builds using common welding wire feedstock—not powder.

Additive builds mean minimal material waste for more effective use of high-performance materials.

Accommodates low volume runs without tooling overheads of conventional manufacturing.

Versatility

Create not only new parts, but repair, refurbish, or modify existing ones.

Dual print heads enable seamless multi-alloy printing and functional grading for targeted functionality.

Wide range of feedstock options, including heat-resistance superalloys.

Innovation

Push performance boundaries with complex geometries and integrated systems.

Rapid prototyping for a faster first article.

Value-added engineering options, including integrated laser serialization.

What We Make

Components for nuclear and energy applications.

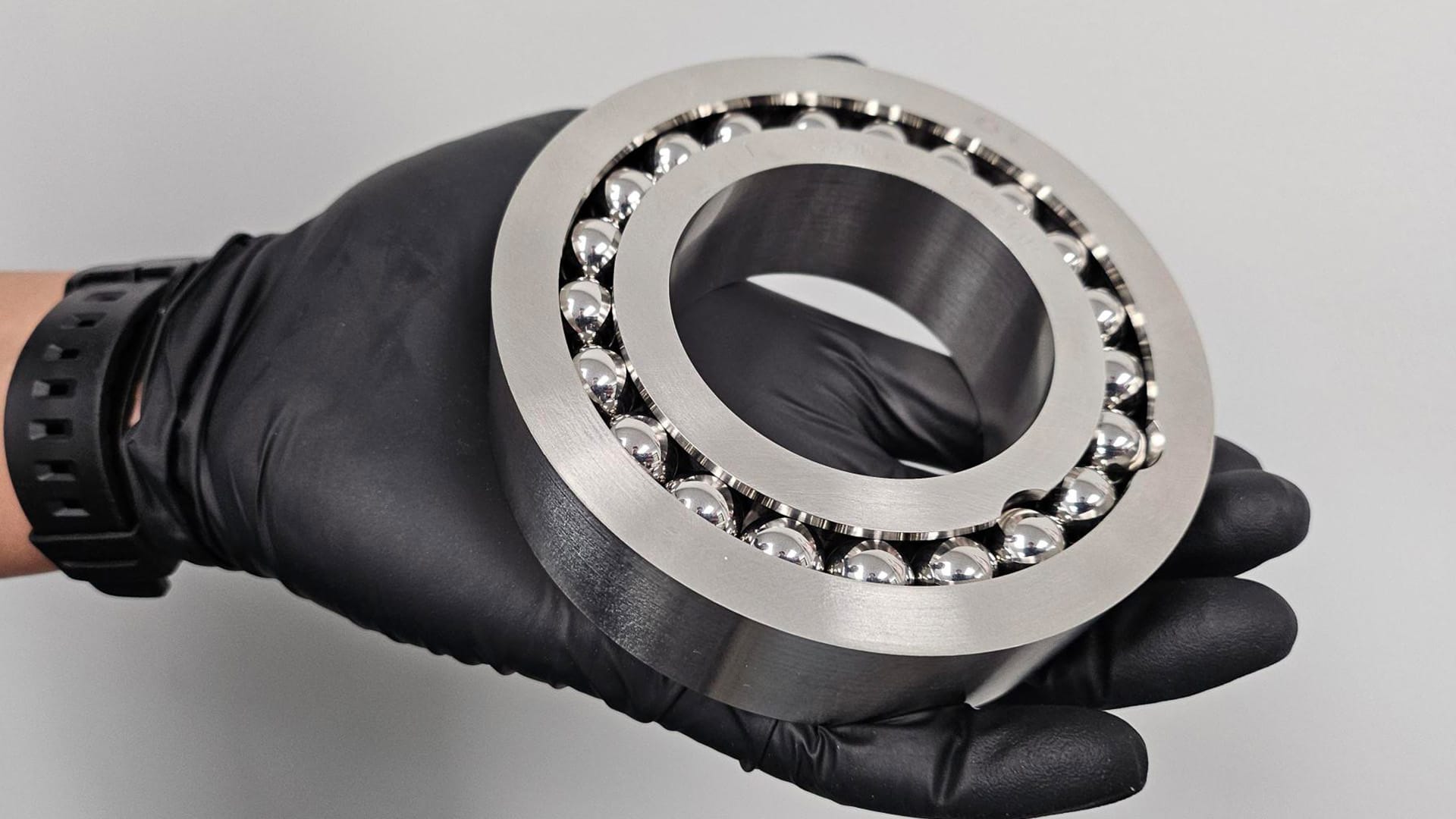

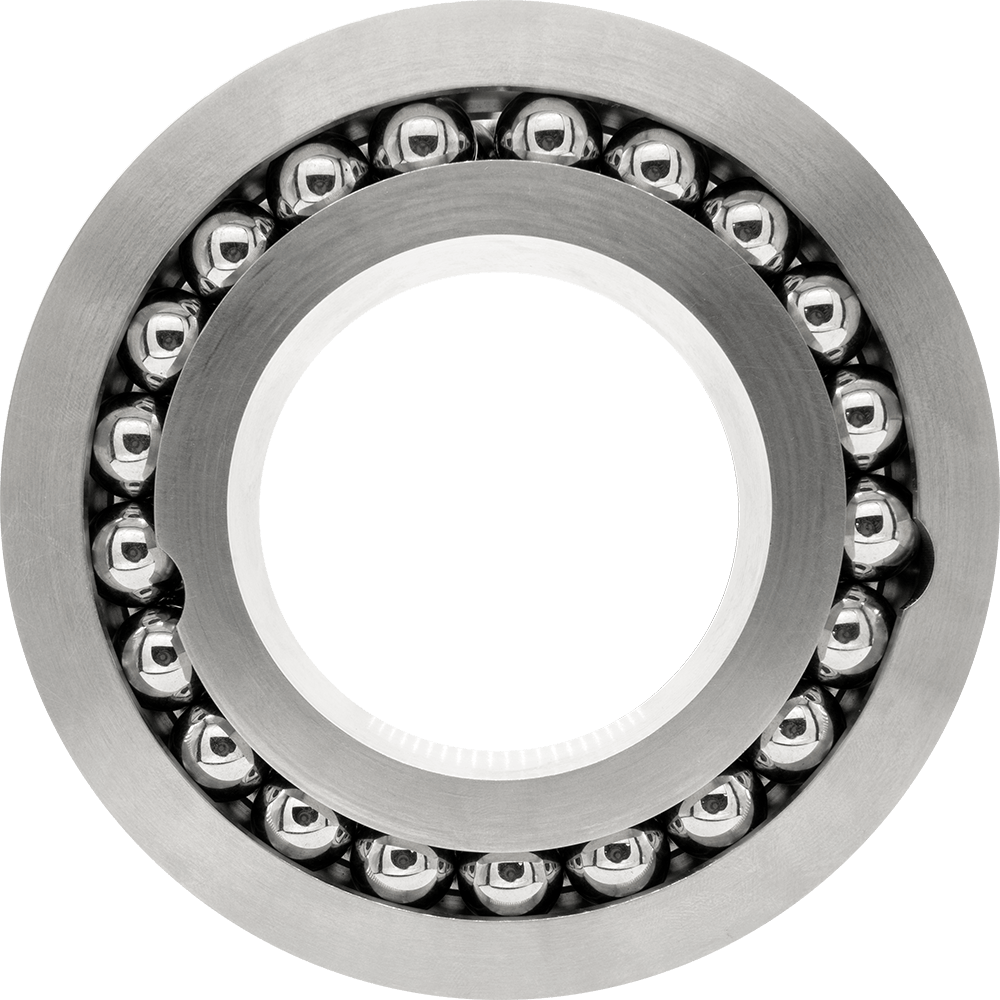

- Bearings (high-temp, corrosion-resistant)

- Housings and enclosures

- Valve bodies and manifolds

- Pump components and impellers

- Precision gears, splines, and couplings

- Roller chain elements

- Related mechanical assemblies

- Dissimilar material overlays and welded transitions (e.g., Ni-base to tool steels, cobalt hardfaces, stainless transitions)

Materials

High-performance materials for high-performance parts.

Heat-resistant superalloys are often rejected due to their expense, supply chain instability, and processing difficulty. We routinely work with nickel- and cobalt-based superalloys, including Inconel® 625 and 718.

The benefits of these high-performance alloys are readily accessible due to the capabilities of wire-laser hybrid manufacturing, including near-net builds, targeted multi-material application, and reliable feedstock supplies.

Selected materials we work with and their relative property applicability.

| Material | Lightness/ Density |

Heat Resistance |

Corrosion Resistance | Hardness / Wear Resistance |

Group | Example Grades |

|---|---|---|---|---|---|---|

| Nickel | – | ◼︎ ◼︎ ◼︎ | ◼︎ ◼︎ ◼︎ | ◼︎ ◼︎ | Heat-Resistant Superalloys | Inconel® 625, Inconel® 718, Inconel® X-750, Hastelloy® C-276 |

| Cobalt | – | ◼︎ ◼︎ ◼︎ | ◼︎ ◼︎ ◼︎ | ◼︎ ◼︎ ◼︎ | Heat-Resistant Superalloys | Stellite® 6, Haynes® 188,Ultimet® |

| Titanium | ◼︎ ◼︎ | ◼︎ ◼︎ | ◼︎ ◼︎ | – | Heat-Resistant Superalloys | Grade 2, Grade 5 |

| Stainless Steel | – | ◼︎ | ◼︎ ◼︎ | ◼︎ ◼︎ | Stainless Steels | 304, 316 P/H, 440C17-4H |

| Carbon Steel | – | – | – | ◼︎ | Steels | 1018, 1045, A36 |

| Tool Steel | – | ◼︎ ◼︎ | ◼︎ ◼︎ | ◼︎ ◼︎ ◼︎ | Hardened Materials | H11, H13, M2, M50, T1, D2 |

| Aluminum | ◼︎ ◼︎ ◼︎ | – | ◼︎ | ◼︎ | Non-Ferrous Metals | 6061, 7075 |

Materials we work with

Selected materials we work with and their relative property applicability:

Heat-Resistant Superalloys

Various Steels

Non-Ferrous Metals

Application

Gen IV Superalloy Bearings

Engineered to withstand the intense environment of a Gen IV reactor, these bearings were custom designed and manufactured using wire-laser DED hybrid manufacturing.

Materials

Superalloys and other high-performance materials chosen for their superior heat- and corrosion-resistance.

Method

Wire-laser DED hybrid manufacturing enabled rapid prototyping and low-volume early-stage quantities.

Quality

Witness coupons produced and tested alongside every build to ensure strict quality control.

Contact Us

+1 (855) 955-7900

info@multiscalesystems.com

49 Canterbury St, Suite 500

Worcester, MA 01610

Quality & Compliance

ISO 9001/AS9100

NIST SP 800-171

DFARS 252.204-7012

CMMC 2.0 Level 2

Copyright © 2023–2026 Multiscale Systems, Inc. All rights reserved.