Industries We Support

Multiscale works in markets where performance, durability, and reliability matter more than volume. Our experience spans energy, aerospace and defense, marine systems, industrial manufacturing, and emerging robotic platforms—particularly where systems operate in extreme or evolving environments.

Problems We Solve

Across industries, we repeatedly encounter the same underlying challenges: components exposed to extreme environments, fragile supply chains, rapid design evolution, and hardware that must perform reliably despite uncertainty.

Rather than organizing our work by industry alone, we frame our experience around applications—technical problem classes that cut across markets and programs.

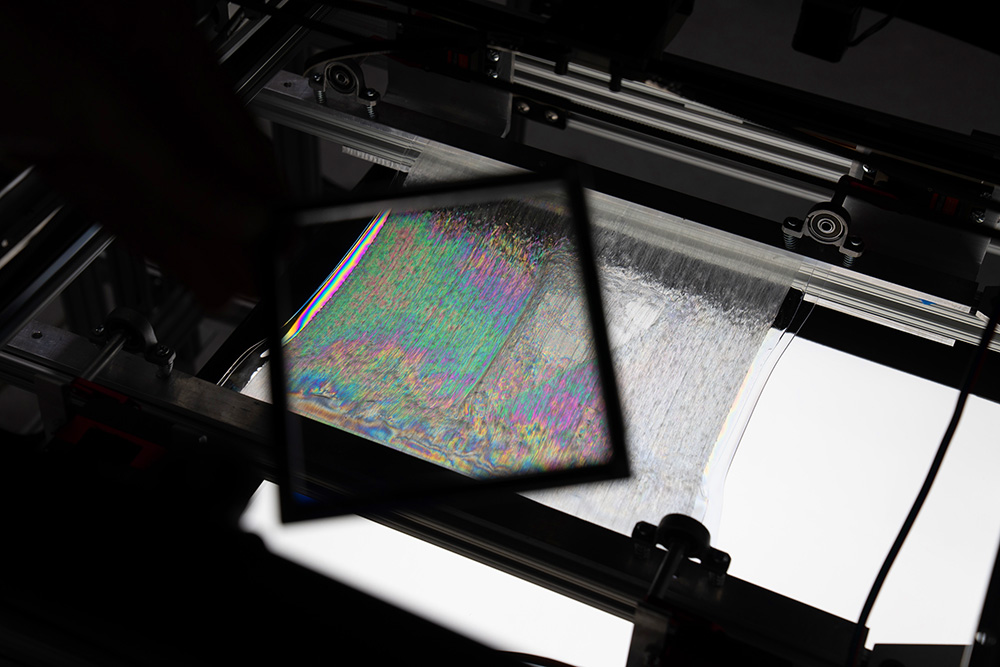

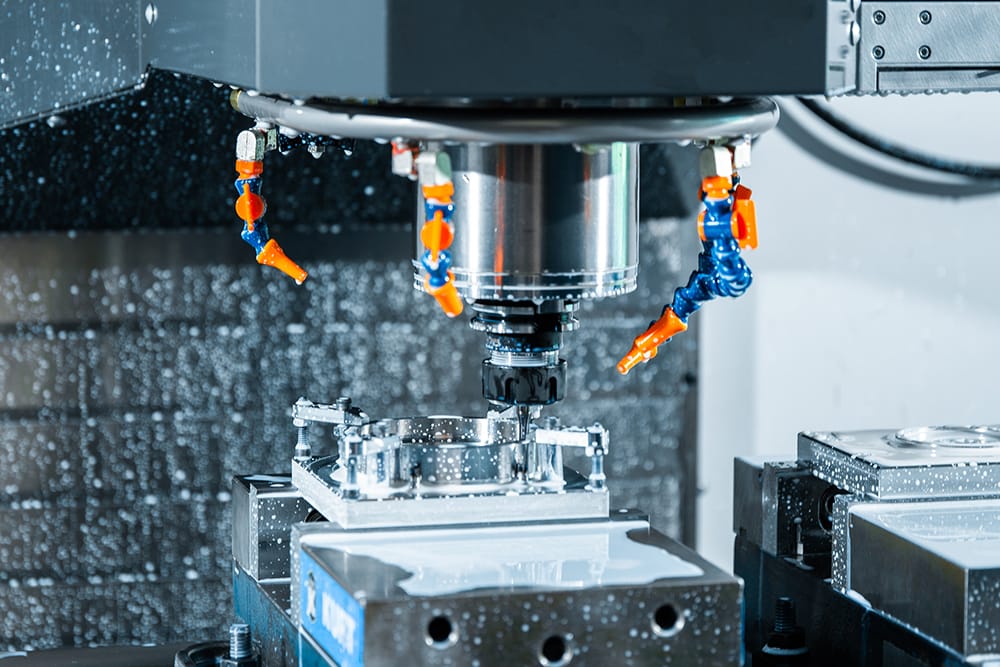

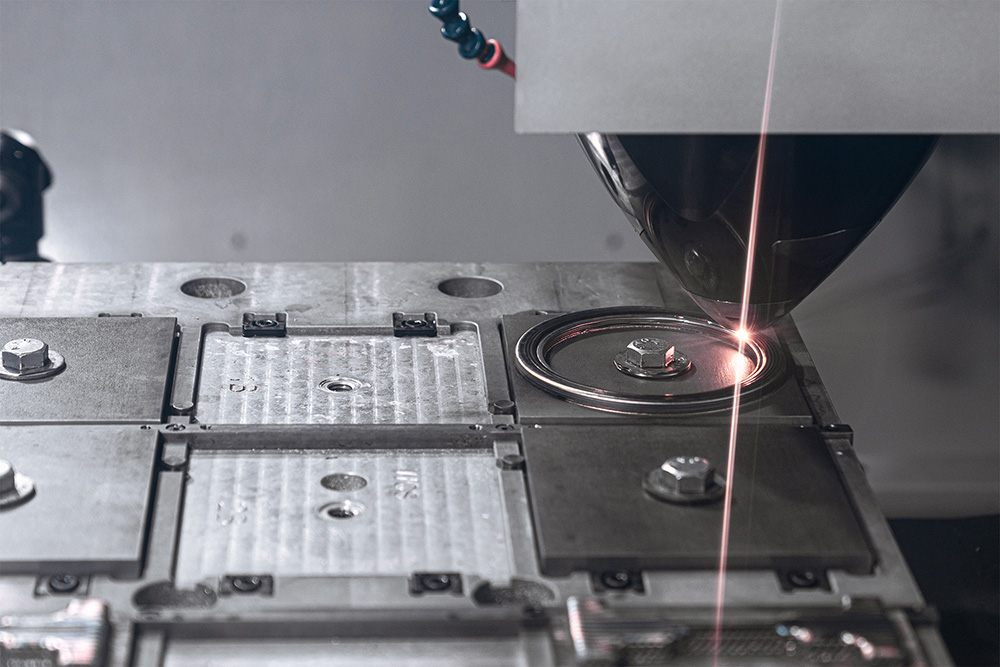

Advanced Capabilities, Applied with Engineering Discipline

Our capabilities span hybrid metal additive and precision machining, polymer forming and composites, tooling and molds, inspection and testing, and engineering-led design for manufacturing.

These capabilities are not offered in isolation; they are applied through structured engagements to reduce risk and deliver predictable outcomes.

Structured Engagements for Complex Programs

Multiscale supports customers through defined service engagements that align technical scope, schedule, and budget. Our services are designed to accommodate discovery while maintaining accountability, especially in programs where requirements evolve.