Executive Summary

Acquisition ROIs

Performance

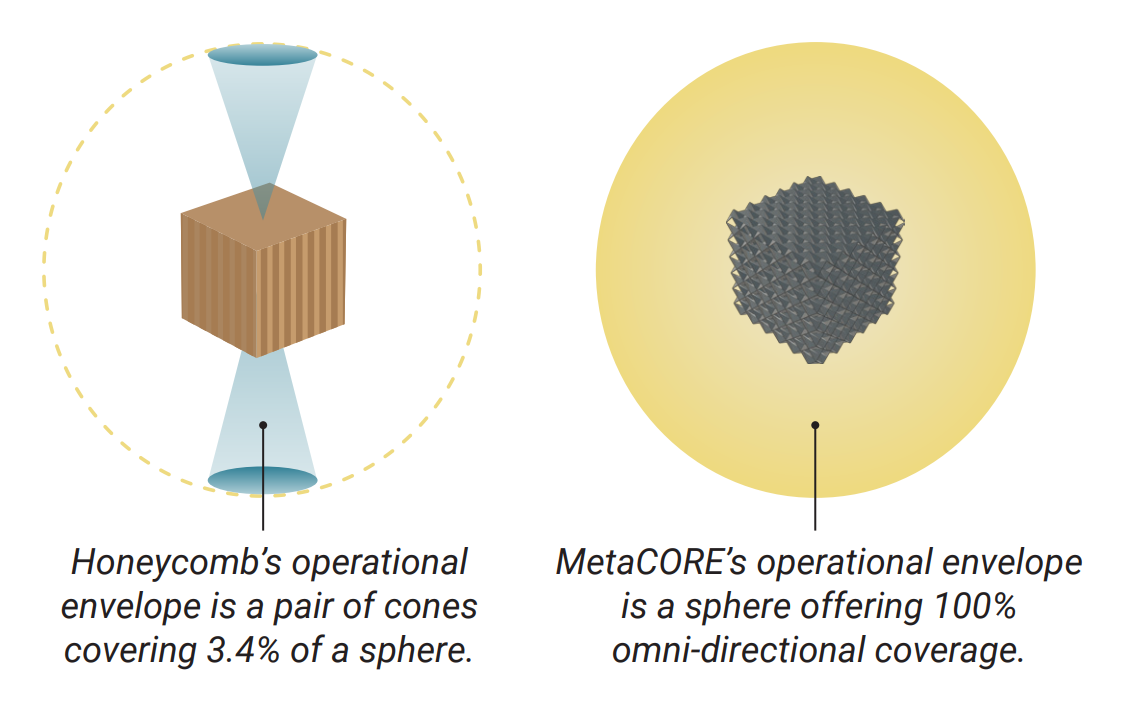

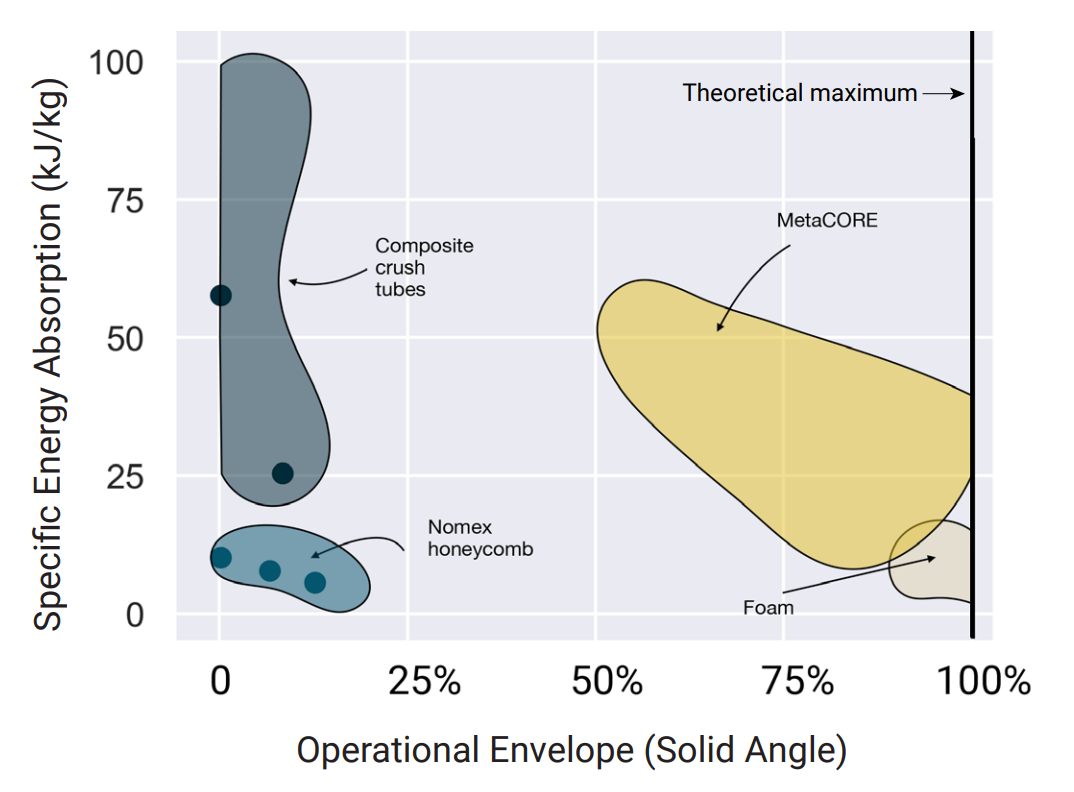

30x improved operational envelope

Size, Weight, Power, Cost

Comparable to current solution

Schedule

Prototype ready for integration testing; 12-24 months to TRL 9

Risk

Comparable to a SBIR Phase II effort

Life Cycle (Obsolesce Risk)

Dual-use technology targeting 5:1 commercial:defense revenues

MetaCORE is a lightweight energy-absorbing replacement for honeycomb that offers 30x improved performance without increasing weight, costs, or logistical challenges.

Focus Area: Soldier Lethality and Survivability through Expeditionary Force Sustainment.

Technology Statement: We make lightweight high-performing energy absorbing materials to mitigate damage from unpredictable high-impact loads.

Impact Statement: “Every pound of payload successfully delivered is another pound of food, water, and equipment for the Soldier.”

Problem Statement: Air dropped payloads require impact-mitigating solutions to ensure cargo is delivered 100% mission capable. Current missions use cardboard honeycomb as an energy absorbing device to “soften” the landing. The operational envelope of cardboard directly constrains payload size, weight, drop times, horizontal glide distances, and speed. Future missions involving large horizontal glides are outside the operational envelope of cardboard honeycomb due to its poor shearing properties

Solution: MetaCORE is an advanced material with isotropic energy absorbing properties that eliminates the 200% to 600% asymmetry in

cardboard honeycomb’s material properties. It was developed by Multiscale Systems under a NASA SBIR Phase I/II contract as a lightweight low-cost material for non-defense aerospace and ground vehicle applications (est. ~$1Bn commercial market). With some modification to the existing manufacturing process, it would be an ideal energy absorber for vastly expanding airdrop operational envelopes. This is a dual-use technology with TRL 4 for aerial delivery applications.

Needs: Manufacturing MetaCORE from natural fibrous/pulp materials is required to be costcompetitive with current cardboard honeycomb and to achieve biodegradability/flammability for easy disposal. Low throughput manufacturing is currently feasible, but further development is required to scale up production.

Value Proposition:

- 30x increase in the operational envelope for impact mitigation compared to honeycomb (see figure below).

- Enabling longer glide distances and larger horizontal speeds necessary to overcome A2/AD threats.

- Manufacturable in a format compatible with existing rigging specifications and agnostic to cargo type.

- Lightweight material increases expeditionary value.

- Natural fiber/pulp-based fabrication adds no additional signature and requires no power source.

- Biodegradable polymer formulation enables heavier payloads while reducing total system mass and volume.

Fast Facts About the Technology and Team:

- Material design technology discovered and developed in the Physics Departments of Cornell University and University of Massachusetts, Amherst, as well as Harvard University’s Wyss Institute.

- Multiscale Systems is a small, domestically owned business in the ASA(ALT) xTechSearch 4 and Innovation Combine cohort of “non-traditionals” with disruptive new technologies responsive to Army modernization priorities. We have experienced stable growth since forming in 2018 by developing advanced materials for dual-use applications.