Crush Force Efficiency (CFE)

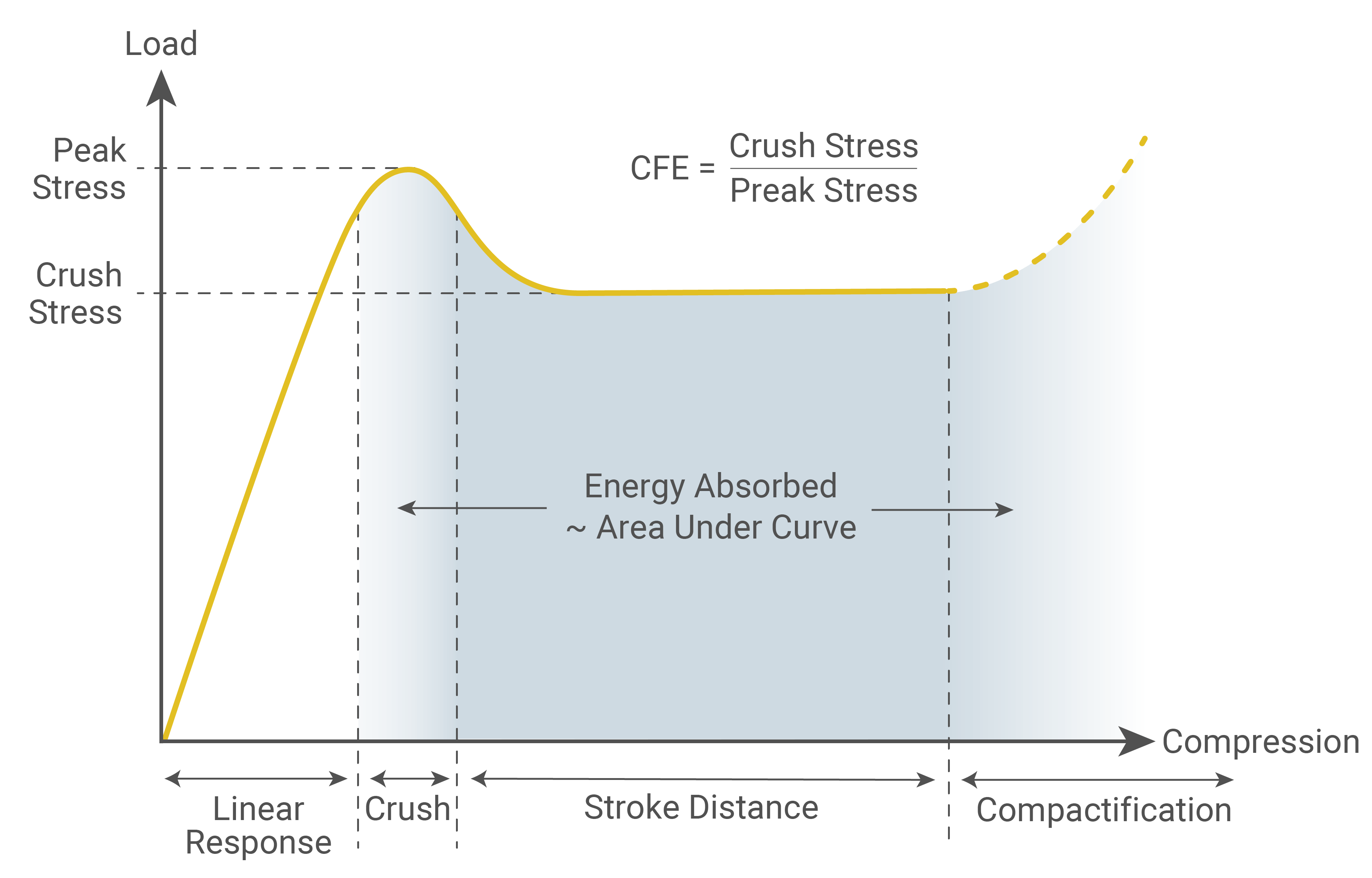

CFE is a ratio of stresses that measure how much force travels through an impact protecting material.

This number is used in aerospace and automotive industries as way of determining the risk of head and neck injuries during a collision, but it can also be used to see how much force would be transmitted to cargo or other supplies.

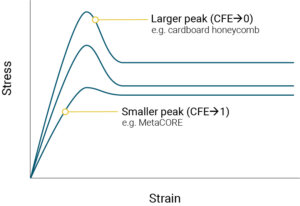

CFE is inversely related to the size of the peak on a stress-strain graph – larger peaks reduce the CFE to 0, offering the least amount of protection, while smaller peaks increase the CFE to its maximum value of 1, offering the most amount of protection:

Our metamaterial composite MetaCORE has a high crush force efficiency

Specific Energy Absorption (SEA)

The SEA is the total area under the flat part of the load-compression curve on the stress-strain graph, divided by the mass of the material that’s become crushed.

A large SEA (> 20 kJ/kg) means lots of energy has been absorbed by the material on impact or that the material absorbing the impact is very lightweight.

Many lightweight, high SEA materials – like honeycomb – are functional in only one direction, meaning they have low SEA and poor impact protection abilities in the other two directions.

Off-axis impacts are generally not effectively dissipated with these materials. In comparison, MetaCORE was designed to be a pro-isotropic, high SEA metamaterial, which overcomes the uncertainty of knowing the impacting direction.