Can’t find what you’re looking for? Contact us, we’d be happy to help.

General FAQs

We are ISO 9001:2015 and AS9100:2016 certified by NQA. View our Certificate of Registration.

We are also NIST SP 800-171 compliant.

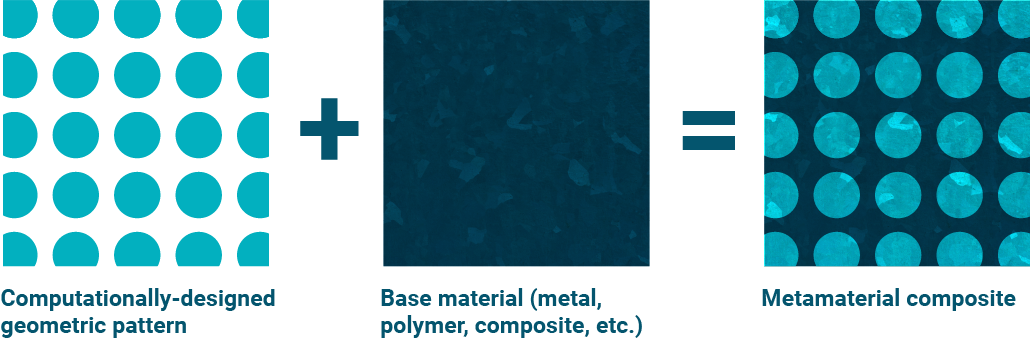

We have developed advanced material solutions for an array of industries, including defense, aerospace, transportation, and energy. Often, metamaterial composites designed for one application can be used across several different industries. An example is MetaCORE, which can be used in impact absorbing defense applications, as well as improving crashworthiness in electric vehicles.

We work with industrial customers who need new or improved advanced material solutions for their product or application. Our services include research and development, design, prototyping, testing, fabrication, and commercialization support. Get in touch with us to discuss your project requirements.

Our in-house R&D program is supported by federal and private organizations. We’ve received several SBIRs from government agencies including the U.S. Department of Energy, the National Science Foundation, NASA, the U.S. Department of Defense, and NIST. We’ve also received various awards and resources from accelerators, local organizations, and partner companies. See a full list of our funders and partners.

Multiscale Systems offers full-spectrum management for technical engineering projects from research and development to design, testing, and fabrication.

We work with our customers to find the best solution for the task at hand. Sometimes that means a solution using metamaterial composites – sometimes not. Each project is assessed individually.

Our focus on advanced manufacturing means we can produce, test, and iterate quickly. It also means we can product highly complex and sophisticated parts that are otherwise impossible to create using conventional manufacturing methods.

Services include technical reporting and writing, research and development, design, manufacturing, and testing and characterization. See our Services page for additional details.

Manufacturing FAQs

Metamaterial composites can be created using a range of methods, including:

- Injection molding

- Thermoforming

- Casting

- Milling

- Pattern transfer

- Additive manufacturing

Yes, additive manufacturing – or 3D printing – is a viable method to produce the necessary metamaterial geometry. It also offers a number of advantages over traditional approaches:

- Metamaterial composite parts can be manufactured at the point and time of need, reducing reliance on supply chain logistics.

- 3D printing allows for relatively low-cost manufacturing, with the costs of materials and equipment becoming increasingly more affordable.

- Designs for 3D printed products can easily be improved and upgraded for new materials, making them future proof.

- By additively manufacturing metamaterial composites, designs can quickly be iterated, tested, and validated, making for quicker development cycles.

Advanced manufacturing refers to the implementation of cutting-edge technologies, innovative processes, and advanced materials in the production of goods. It’s a modern approach to manufacturing that goes beyond traditional methods by leveraging the latest advancements in technology and automation to enhance the efficiency, productivity, and quality.

Key characteristics of advanced manufacturing include:

- Technology integration: Advanced manufacturing involves the integration of emerging technologies like AI, robotics, Internet of Things, 3D printing, and data analytics into the manufacturing process.

- Customization and flexibility: Greater customization and flexibility in production allows manufacturers to quickly adapt to changing market demands and produce customized products.

- Sustainability: Advanced manufacturing emphasizes eco-friendly practices by optimizing resource utilization, minimizing waste, and reducing the overall environmental impact of production.

- Additive manufacturing: 3D printing is a prominent aspect of advanced manufacturing, enabling the creation of complex and lightweight designs with improved precision.

Benefits of advanced manufacturing include:

- Enhanced productivity and reduced production times

- Improved product quality and consistency

- Lower production costs through optimized processes and resource management

- Faster product prototyping and development cycles

- Increased competitiveness in the global market

Multiscale Systems uses several aspects of advanced manufacturing, including the use of our hybrid metal 5-axis CNC system; high-temperature thermoplastic printer; and conventional 3D printer print farm.

Hybrid manufacturing is a cutting-edge production approach that combines additive manufacturing (3D printing) with traditional subtractive processes like milling or machining. This innovative technique leverages the advantages of both methods, enabling the creation of complex and highly customized parts with improved efficiency and precision.

Additive manufacturing is used to build intricate geometries and intricate details, while subtractive processes are employed to refine the surfaces and achieve precise dimensions. Hybrid manufacturing finds applications in aerospace, medical, and automotive industries, where it offers the flexibility to produce intricate components with reduced material waste and faster production cycles. It also allows for mixed-alloy components.

Multiscale Systems employs a metal hybrid 5-axis CNC system. Ask us how hybrid manufacturing can improve your product.

Thermoforming is a manufacturing process used to shape thermoplastic materials into various products.

Vacuum thermoforming involves heating a plastic sheet until it becomes pliable, then forming it over a mold using pressure and a vacuum. Once cooled, the plastic takes the shape of the mold. Common items that are created using thermoforming include packaging, trays, and consumer goods.

Similarly, pressure forming is a process that involves heating a thermoplastic sheet and then applying pressure from both sides of a mold to force the material into the desired shape.

Thermoforming is cost-effective, enables rapid production, and allows for intricate designs. It finds applications in industries such as food packaging, automotive, medical, and consumer goods, making it a versatile manufacturing technique.

Multiscale Systems regularly utilizes both thermoforming and pressure forming in the development and production of our products.

Metamaterial composites FAQs

Technical FAQs

Crush Force Efficiency (CFE)

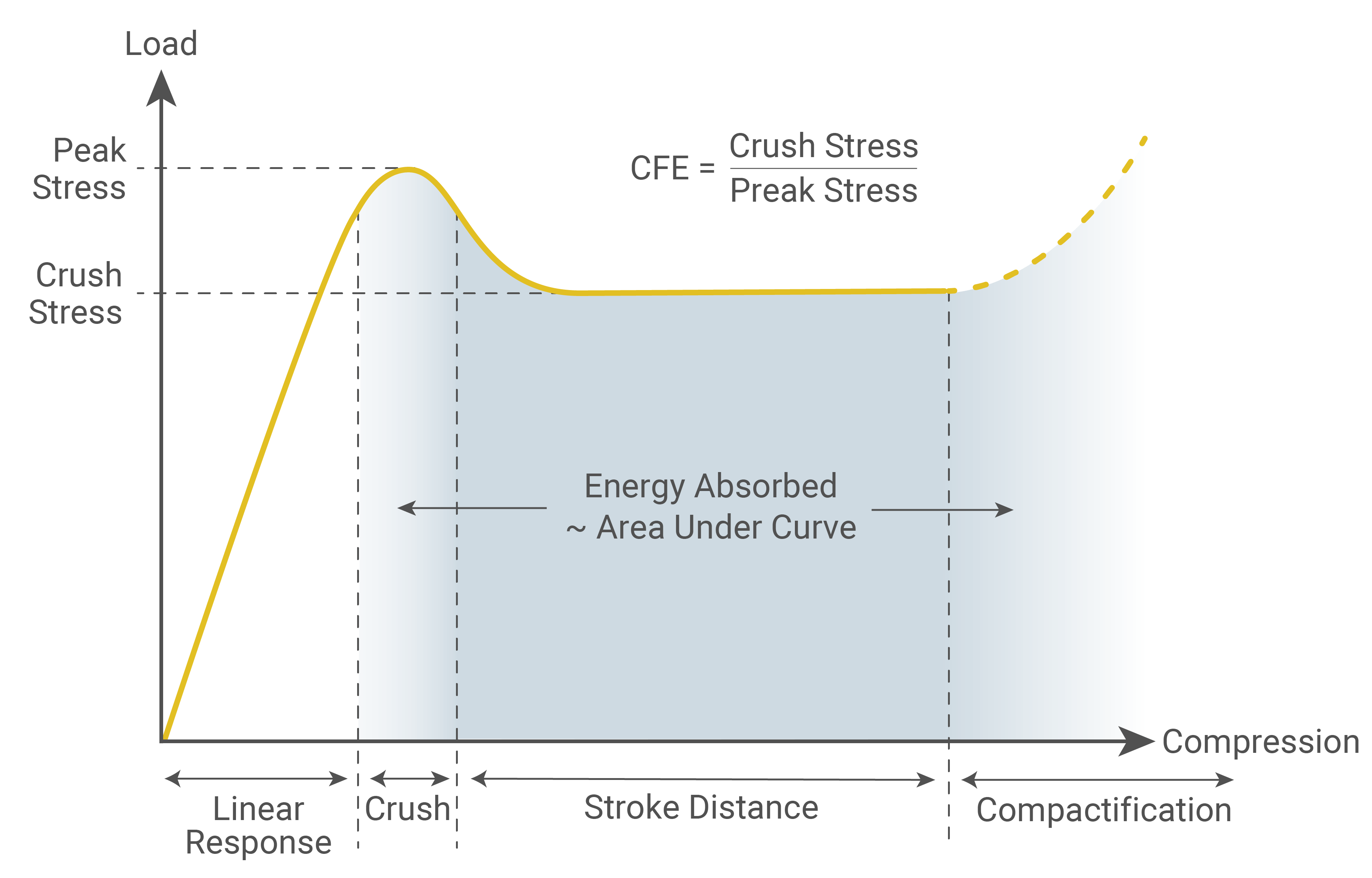

CFE is a ratio of stresses that measure how much force travels through an impact protecting material.

This number is used in aerospace and automotive industries as way of determining the risk of head and neck injuries during a collision, but it can also be used to see how much force would be transmitted to cargo or other supplies.

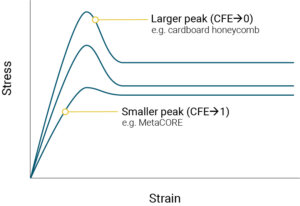

CFE is inversely related to the size of the peak on a stress-strain graph – larger peaks reduce the CFE to 0, offering the least amount of protection, while smaller peaks increase the CFE to its maximum value of 1, offering the most amount of protection:

Our metamaterial composite MetaCORE has a high crush force efficiency

Specific Energy Absorption (SEA)

The SEA is the total area under the flat part of the load-compression curve on the stress-strain graph, divided by the mass of the material that’s become crushed.

A large SEA (> 20 kJ/kg) means lots of energy has been absorbed by the material on impact or that the material absorbing the impact is very lightweight.

Many lightweight, high SEA materials – like honeycomb – are functional in only one direction, meaning they have low SEA and poor impact protection abilities in the other two directions.

Off-axis impacts are generally not effectively dissipated with these materials. In comparison, MetaCORE was designed to be a pro-isotropic, high SEA metamaterial, which overcomes the uncertainty of knowing the impacting direction.

Technical data can be found in Resources, including datasheets, white papers, and case studies.