WORCESTER, Mass. (July 12, 2024) – Multiscale Systems, in partnership with the Venture Forum, has been awarded a Massachusetts Manufacturing Innovation Initiative (M2I2) grant to build a new facility in Worcester and to expand its manufacturing capacity with the acquisition of additional advanced equipment.

The matching grant program through MassTech Collaborative’s Center for Advanced Manufacturing (CAM) is intended to help Massachusetts organizations transition their technologies to manufacturing by bridging the gap between innovation and commercialization.

Christine Nolan, Director of CAM, announced the 13 M2I2 grant awardees at a ceremony in Holyoke, MA on July 11.

Multiscale CEO and Research Director, Jesse Silverberg: “It’s a new era for Multiscale Systems as we expand our advanced manufacturing capabilities. We are also excited to support our community through the creation of jobs and apprenticeships in the manufacturing sector.”

Image: The M2I2 awards ceremony in Holyoke, MA on July 11, 2024. Left to right: Christine Nolan (Director, Center for Advanced Manufacturing), Yvonne Hao (Massachusetts Secretary of Economic Development), John McCarthy (Corporate Development Specialist, Quinsigamond Community College), Jesse Silverberg (CEO/Research Director, Multiscale Systems), Zak Dutton (Executive Director, Venture Forum), Patrick Royce (VP Business Lending, Webster Five), Carolyn Kirk (CEO, MassTech Collaborative). Image © Multiscale Systems.

New facilities and job creation

Multiscale Systems will use the $1,111,690 matching grant to build a dedicated advanced manufacturing facility in Worcester, MA, and to purchase new machinery that will expand the capacity of Multiscale’s rapidly growing manufacturing subsidiary, Hybrid CNC Parts, to provide additional custom and turnkey fabrication of innovations for advanced industries.

Up to 10 jobs will be created using this grant investment. Multiscale will also be partnering with Quinsigamond Community College to create a registered apprenticeship program, and will engage with the Venture Forum’s entrepreneurship network. The project is aligned with three Manufacturing USA Institutes: America Makes, The Cybersecurity Manufacturing Innovation Institute, and Advanced Robotics for Manufacturing Institute.

Advanced manufacturing hub in Worcester

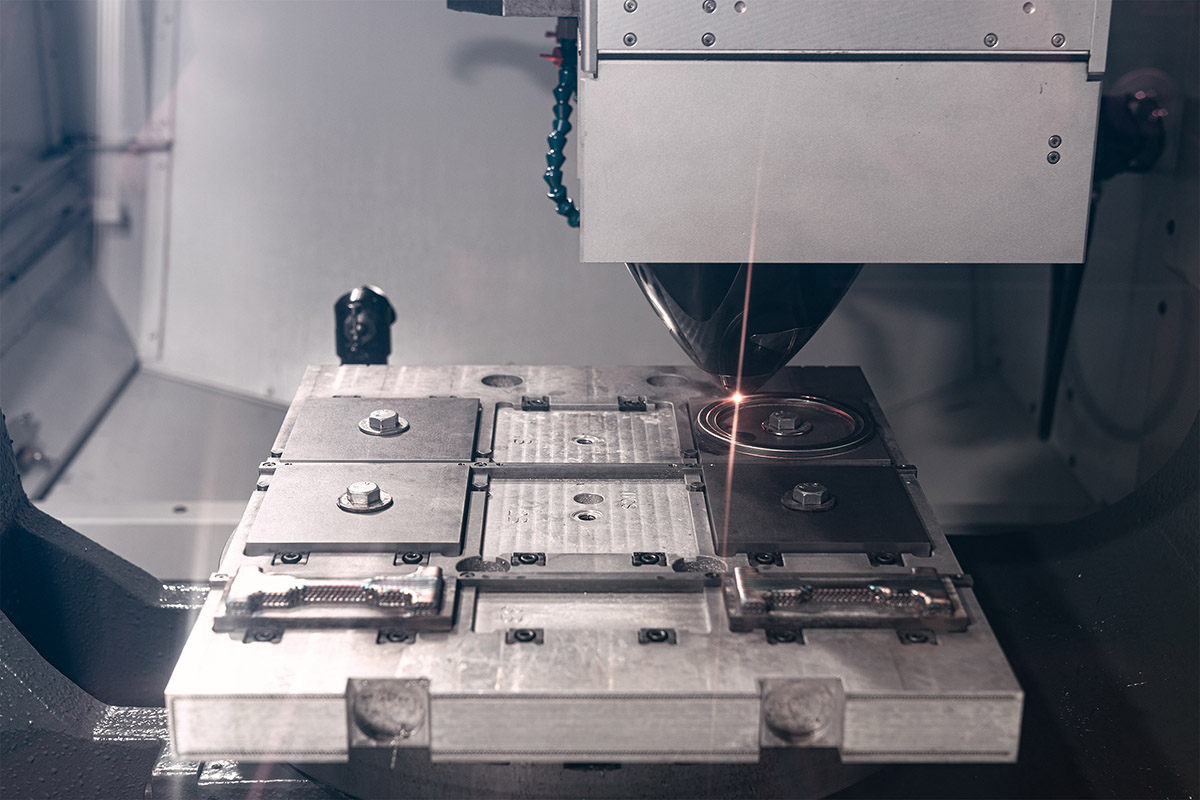

Hybrid CNC Parts utilizes metal hybrid manufacturing technologies that combine additive and subtractive capabilities within a single system. This advanced manufacturing method can efficiently create, repair, or enhance metal components, often with complex geometries and integrated functionalities.

New advanced manufacturing equipment will include:

- Two (2) Haas-Meltio metal hybrid manufacturing systems.

- One (1) Haas CNC machine.

- One (1) Hexagon GLOBAL Scan+ coordinate-measuring machine for full-part inspection and verification.

The equipment acquisition aligns with the temporary relocation of Hybrid CNC Parts to Multiscale Systems’ Canterbury Street headquarters in Worcester, MA while the new facility is being developed. In addition to the expansion of its additive and hybrid manufacturing capabilities, the move allows for closer collaboration between Multiscale’s engineering and manufacturing teams, and will function as a hub for advanced manufacturing in the heart of the Commonwealth.

Image: A bearing part being 3D printed using one of Hybrid CNC Parts’ metal hybrid manufacturing systems. Image © Multiscale Systems.

Multiscale Systems drives innovation and engineering design for advanced industries using thermoplastic composites and metal additive manufacturing.

Hybrid CNC Parts specializes in Inconel®, Stellite®, and other performance materials and metal hybrid manufacturing. Capabilities focus on high-mix, low-volume custom production with an emphasis on quality, precision, and unique requirements. It is a wholly-owned subsidiary of Multiscale Systems and part of the Multiscale Group of companies.

###

Media Inquiries

Karen Tisdell

Communications Director

info@multiscalesystems.com

Latest Lab Notes

News /

July 18, 2025—Multiscale will engineer functionally-graded alloys tailored for molten salt and liquid metal environments, leveraging its hybrid manufacturing systems to produce nuclear-grade material performance.

News /

March 11, 2025 – Multiscale Systems to showcase cutting-edge industrial innovation during StartUp Week Worcester 2025.

News /

Multiscale Systems receives Massachusetts manufacturing award in recognition of outstanding leadership skills in the manufacturing industry.