WORCESTER, Mass. (August 7, 2023) – Multiscale Systems has been awarded a trio of Small Business Innovation Research (SBIR) awards through NASA and the Department of Energy (DOE).

The SBIRs awarded are:

- NASA: Wire Laser Metal 3D printed bearings for extreme environments.

- DOE: Bimetallic functionally graded materials for high-temperature corrosion resistance.

- DOE: Hydrogen transportation and storage components made with metal hybrid additive and subtractive manufacturing.

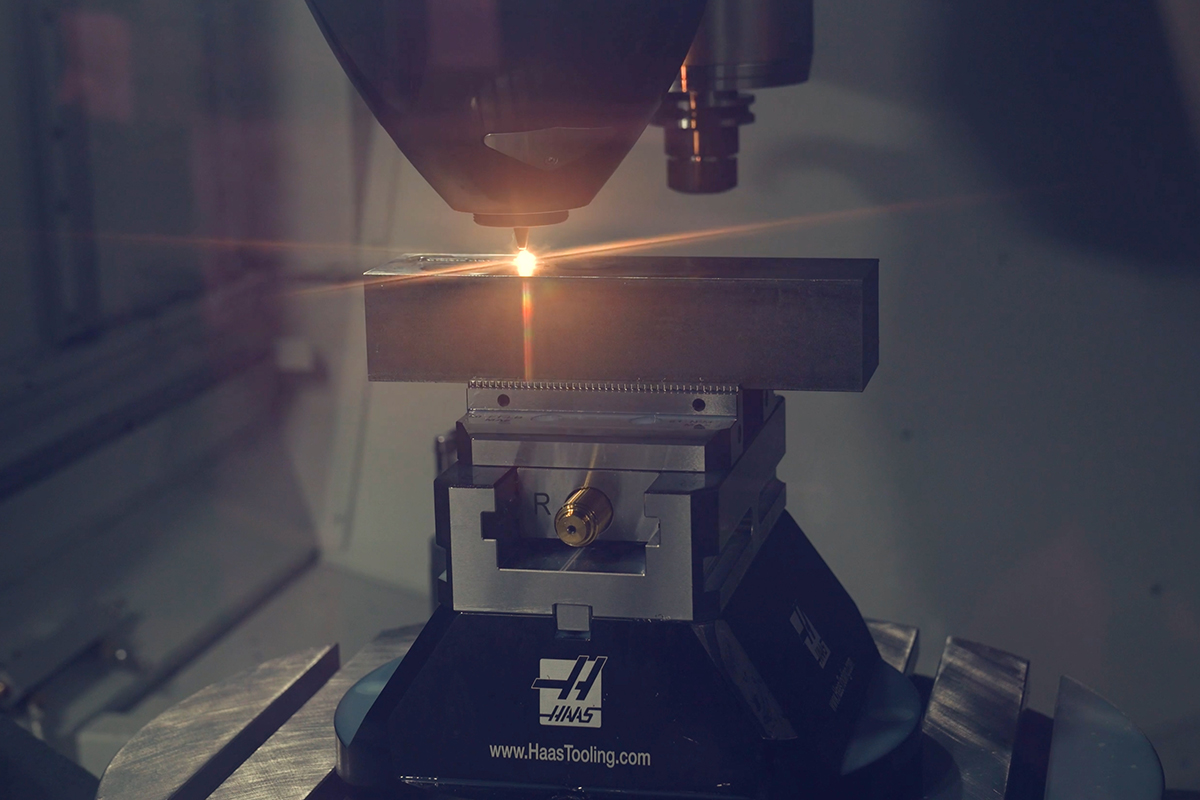

While each award has its own particular focus, the common thread running through each is the utilization of hybrid manufacturing.

Hybrid manufacturing is a process that contains both additive and subtractive manufacturing within the same system. It allows for highly complex parts to be created faster and with less material waste compared to conventional manufacturing methods, and allows for the use of mixed alloys within the same component.

Bearings for extreme environments

NASA has awarded Multiscale Systems an SBIR to develop bearings that can handle the extreme conditions found within our solar system. Exploring and studying the outer planets is crucial for understanding the origins of life and planetary evolution.

But there are challenges, including extreme environmental conditions ranging from cryogenic temperatures (the -364 °F surface of Europa) to corrosive atmospheres (Venus’ 932 °F atmosphere). Understandably, equipment survivability and mechanical failure are major concerns.

Hybrid manufactured bearings offer the benefits of lightweighting, design complexity, and the ability to create alloy composites with high ductility, controllable thermal expansion, and corrosion resistance, which will drastically increase their chances of survival in these extreme conditions.

Bimetallic materials for the energy sector

Two DOE SBIRs also focus on hybrid manufacturing. The first, for bimetallic materials that will withstand high temperatures and corrosive environments within the energy sector, will take advantage of hybrid manufacturing’s ability to mix metals during the additive manufacturing stage.

Cryogenic valves

Multiscale Systems’ second DOE SBIR will explore embrittlement-resistant cryogenic valves using metal additive manufacturing. With rising energy demands, hydrogen is becoming a more popular fuel choice. However, the cryogenic conditions required for its storage and transportation can be problematic, with components failing due to the extreme cold. Multiscale will explore hybrid manufacturing solutions that address this critical issue.

“Advanced energy concepts like cryogenic hydrogen and liquid metal-cooled nuclear reactors have the potential to change the way we fuel our lives. But conventional manufacturing is unable to make the required high-performance parts at acceptable costs or in sufficient amounts. Multiscale Systems understands the performance needs for these extreme environments, and we can design and manufacture components that meet the required specifications,” said Art Evans, CTO and Research Director.

Awarded for innovation

Previous awards granted to Multiscale Systems include:

- NIST: Contact-free optical metrology QA/QC polariscope for large-scale manufacturing systems.

- DOE: Additively manufactured bearings for nuclear reactors.

- NASA: Accelerated aging of metamaterial composites in low-Earth orbit.

- DOE: Vibration-reducing solution in hydroelectric power generation.

- NASA: Metamaterial composite development for mitigating impacts of UAMVs.

Multiscale Systems is a multi-disciplinary team that creates advanced material solutions for new and improved products, systems, and applications. From ideation through to commercialization, we provide technical engineering and manufacturing services to our clients. Our R&D portfolio includes work in aerospace, energy, transportation, and more.

###

Media Inquiries

Karen Tisdell

Communications Director

info@multiscalesystems.com

Asset gallery

Latest Lab Notes

News /

March 11, 2025 – Multiscale Systems to showcase cutting-edge industrial innovation during StartUp Week Worcester 2025.

News /

Multiscale Systems receives Massachusetts manufacturing award in recognition of outstanding leadership skills in the manufacturing industry.

Press Release /

WORCESTER, Mass. (July 12, 2024) – Multiscale Systems to build new facilities, expand advanced manufacturing capabilities, and bring jobs to Worcester with grant investment.