Multiscale supports complex engineering and manufacturing programs where conventional supplier models fail. Our services are structured to manage technical risk and execute difficult hardware.

Integrated Development to Production

Engineering continuity from early uncertainty to production reality.

We support teams developing complex systems where design intent, material behavior, and manufacturing constraints evolve together. Rather than engaging at a single phase, we remain accountable from early development through production-ready hardware.

Best suited for teams that:

- Are developing a system, not just an isolated part.

- Expect design iteration and unresolved technical risk.

- Need engineering judgment, not just build-to-print execution.

- Can’t afford failure during the transition from development to production.

- Want a supplier that will still be engaged once the design stabilizes.

What We Deliver

- Early input on Design for Manufacturing (DFM) and Design for Inspection (DFI).

- Materials selection and validation.

- Process development (additive, subtractive, hybrid workflows).

- Prototype builds and iteration.

- First article inspection and production readiness planning.

- Seamless transition to repeatable manufacturing.

What Makes Our Approach Different

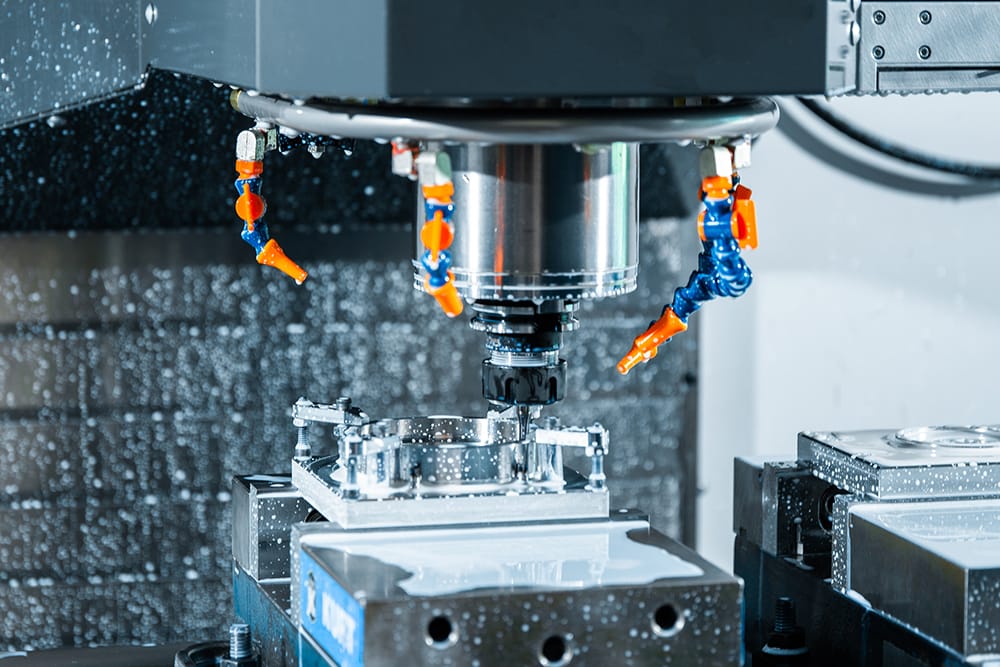

We manufacture difficult hardware that does not fit traditional production models—complex geometries, demanding materials, tight tolerances, or hybrid process requirements.

Our services is designed for:

- Low-volume, high-consequence hardware.

- Programs requiring hybrid manufacturing workflows.

- Parts that require advanced inspection or validation.

- Customers needing engineering support alongside manufacturing.

Our integrated CNC, additive, metrology, and lab capabilities allow us to deliver hardware that is both technically sound and inspection-ready.

How We Engage

All services are structured around clearly defined technical outcomes.

We do not allow scope to drift informally. As new constraints emerge—materials behavior, manufacturability limits, inspection realities, or supply-chain constraints—we evaluate impacts to cost and schedule and formalize adjustments through structured scope modifications.

This approach preserves technical rigor, predictable execution, and alignment between expectations and results.