Reliable materials for high-temperature, high-pressure applications

Achieving utility scale geothermal energy is bottlenecked by the cost of equipment failure in extreme downhole environments. New materials are required to unlock the potential of Enhanced Geothermal Systems (EGS).

Outcomes: New IP created and licensed; job creation

Technology development:

MetaTHERM

Funding:

SBIR Phase I

Geothermal Manufacturing Prize

Subsurface resources beyond oil and gas

Most of human civilization’s greatest feats were accomplished with resources found underground. Whether it be ornate bronze age metalwork or advanced petrochemicals used in spacecraft , finding, collecting, and processing underground resources was the first step for all these historic achievements.

However, a side effect of a historical perspective is that it can limit our mindset, skewing and obscuring new ideas. For example, pick any location on the Earth and go down a few kilometers. The ambient temperature will be hot enough to boil water, but it’s not obvious to think of heat as an underground resource on par with metal or oil – even though it can be collected and processed to power entire cities.

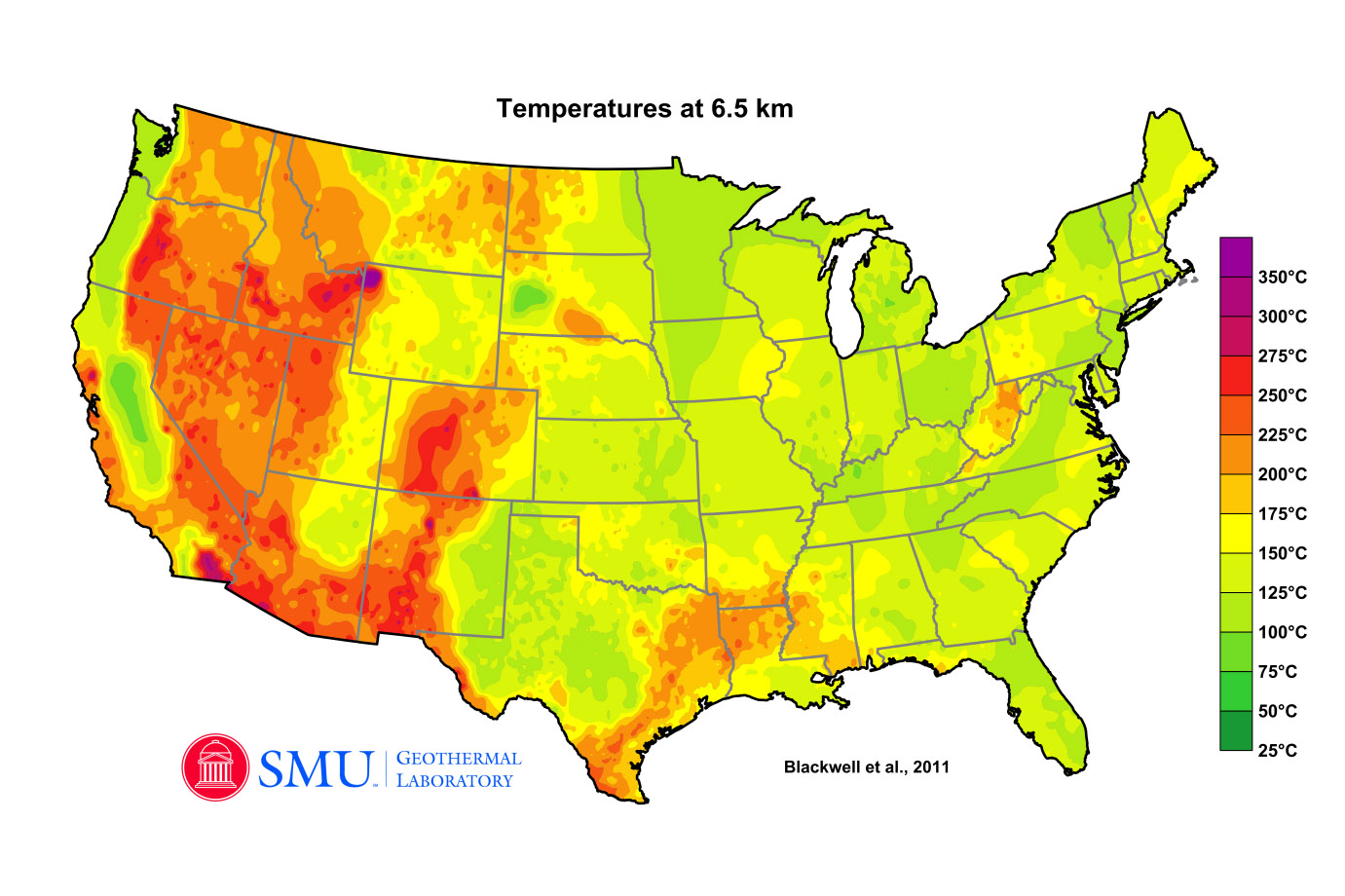

A map of the continental United States depicting temperatures at a depth of 6.5 km. Source: Blackwell et al., 2011.

Geothermal’s payoff is pretty good, actually

In the 2019 GeoVision report , the US Department of Energy’s Geothermal Technologies Office summarized the benefits of geothermal energy:

- Secure, “always-on”, renewable electricity generation with flexible support capabilities essential for the grid of the future

- Nationwide affordable solutions for electricity generation

- Useful for both heating and cooling residential and commercial properties

- Built on existing commercial technologies that are already proven in the market, but enhanced by modern innovations

- Vast economic and environmental benefits at local and national levels

Hard to reach places

Given the benefits of geothermal energy, the question becomes: why aren’t we already using it? We already know how to drill and access subsurface resources like metals and oil, so what’s the hold up?

It turns out, these reasonable questions have some surprising answers.

Essentially, the increased depths required for geothermal energy present such extraordinarily challenging conditions that oil and gas drillers (despite their decades of experience, expertise, and specialized equipment) can’t efficiently create deep enough wells. For utility-scale energy production, a geothermal well reaches depths where the heat and pressure cause water to go supercritical . The rock face becomes intensely hard, abrasive, and the naturally occurring environment is intensely corrosive. Metal casing pipes used to keep the well from collapsing undergo so much thermal expansion that the metal yields from heat alone.

Taken together, these factors accelerate wear and tear on the drilling equipment, causing the likelihood of failure to increase dramatically and the cost of drilling to become exponentially expensive with depth.

Equipment suitable for oil and gas drilling just isn’t rugged enough to survive in the hard, hot, extreme environments for utility-scale geothermal energy.

This abundant renewable energy resource – heat – may be below our feet, but it’s in an extremely hard to reach place.

High temperature thermomechanical metamaterials

At Multiscale Systems, we tackled these problems with support from the US Department of Energy. Funding through a Small Business Innovative Research contract led to the development of thermomechanical metamaterials engineered to specifically target the reasons wells fail, allowing us to tackle the cost drivers currently bottlenecking geothermal energy.

The MetaTHERM class of metamaterials includes a reliable replacement for elastomers used in high-temperature, high-pressure sealing applications, and a robust solution for overcoming casing failure. New material solutions like these are necessary to unlock the potential of utility-scale geothermal energy.

Multiscale Systems’ application video for the Make! stage of the US Department of Energy’s Geothermal Manufacturing Prize .

Explore our technology development case studies

National Science Foundation

How our metamaterial research evolved into a targeted commercialization strategy for MetaCORE-LD as an alternative lightweight sandwich panel for semi-trailers.

Department of Defense

Lessons learned from xTechSearch and technology development within the US Army.

NASA

Developing lightweight crash mitigation technology in preparation for the emerging UAMV market.

National Institute of Standards and Technology

Non-destructive testing of complex 3D geometry with optical metrology opens the door to high-quality mass production.