3D printing is an essential prototyping and manufacturing method we use in the development of our mechanical metamaterials. But what is 3D printing exactly and how is it helpful?

What is 3D printing?

Simply, 3D printing creates three-dimensional objects from a digital file. As an additive manufacturing process, 3D printing is done by a machine that places consecutive layers of a material onto a print bed to create an object. The many print layers can be thought of like rings on a tree – each pass of the printer adds another thin layer of material, eventually building up to create a 3D-printed item.

Why use 3D printing?

Why 3D print an item instead of using a more traditional manufacturing method, like milling or pattern transferring? It’s extremely effective in fabricating complex structures, quickly creating prototypes, and providing easy access to a variety of affordable materials. Traditional manufacturing often involves expensive equipment, requires a lot of time and physical space, and usually needs a lot of raw materials – all issues that can be avoided with 3D printers.

For example, 3D printing is gaining traction in dentistry, with items such as crowns, bridges, and dentures being additively manufactured on demand and customized to each patient. Customization, combined with a low cost per unit, make 3D printing an attractive mass production option.

3D printing prototypes of mechanical metamaterials

What are mechanical metamaterials?

Mechanical metamaterials, like MetaCORE, are structured materials that can be engineered with a wide range of exotic responses to external forces. They’re created by embedding geometric patterns into common base materials without making chemical or molecular modifications.

Mechanical metamaterials are what Multiscale Systems designs and manufactures, and they are applicable to almost anywhere you need a material, from aerospace and transportation to defense applications and building materials.

Some characteristics of mechanical metamaterials include high strength, low density, isotropic impact absorption, high thermal insulation, and negative Poisson effects, making them a truly versatile and unique advanced material solution.

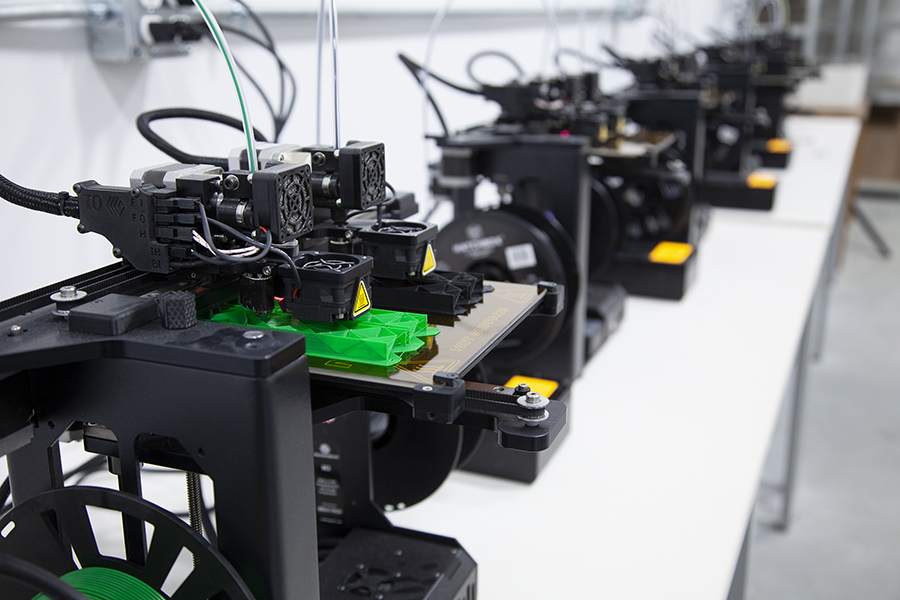

Image: Print farm consisting of six MakerGear M3-ID dual extruder 3D printers.

How we use 3D printers to make mechanical metamaterials

The first step in creating a mechanical metamaterial is to design and optimize its geometry, which we do computationally with software. We then digitize that design in a 3D-modeling program. Once we have the 3D file, we can send it to one of our MakerGear 3D printers or to our high temperature 3DGence printer to create a prototype.

GIF: 3D printed prototype in PEEK, using our 3DGence Industry F350 printer.

We usually 3D print a variety of prototypes using different speeds, materials, rafts, and skirts. Rafts and skirts are different ways to help keep the print stable on the print bed (rafts are a few temporary layers under your print, so that it isn’t printed directly onto the bed. Skirts are also temporary, and are thin layers that encircle the print to help it “stick” to the bed).

Each prototype is then tested to determine which geometry and print settings best produced the desired properties for that mechanical metamaterial.

Our R&D process involves a cycle of designing, testing, and validating. One prototype is never enough, and after testing we usually modify the original design, print, and test again.

3D printers make rapid prototyping fast, easy, and affordable – providing a tremendous advantage in the development of new metamaterial technology and their commercial applications – and help us turn ideas into items.

Latest Lab Notes

News /

March 11, 2025 – Multiscale Systems to showcase cutting-edge industrial innovation during StartUp Week Worcester 2025.

News /

Multiscale Systems receives Massachusetts manufacturing award in recognition of outstanding leadership skills in the manufacturing industry.

Press Release /

WORCESTER, Mass. (July 12, 2024) – Multiscale Systems to build new facilities, expand advanced manufacturing capabilities, and bring jobs to Worcester with grant investment.

Talya Feldman is a Manufacturing Intern for Multiscale Systems and a senior at Worcester Polytechnic Institute, pursuing a degree in Mechanical Engineering and Theater.

Talya Feldman is a Manufacturing Intern for Multiscale Systems and a senior at Worcester Polytechnic Institute, pursuing a degree in Mechanical Engineering and Theater.