Customers take the lead on developing a MetaCORE-LD product for semi-trailers

In 2019, we won an NSF SBIR for development of mechanical metamaterials. What began as a general desire to do something with our metamaterial research evolved into a targeted commercialization strategy for MetaCORE-LD as an alternative lightweight sandwich panel for semi-trailers.

Outcomes:

MetaCORE patent/trademarks; 2 full-time staff

Technology development:

MetaCORE, MetaCORE-LD

Funding:

NSF SBIR Seed Fund

Getting innovations out of the lab and into the market

In the United States, federally funded research generates countless academic papers and endless amounts of data. But among all those measurements, how many scientific discoveries never leave the lab? How many new technologies are never actually brought to life? Could potential world-changing inventions be forever undeveloped?

At our core, Multiscale Systems is focused on commercializing the PhD and postdoctoral research of founders Drs. Silverberg and Evans. But technical know-how in itself is insufficient for bringing new technologies to market.

Bridging that gap between academics and commercialization

With funding and support from the U.S. NSF seed fund, Multiscale Systems took the first steps of its commercialization journey. NSF saw two PhD-level physicists working from home offices and a garage, recognized the commercial potential of the technology, and made one thing extremely clear: we had to close our laptops, get out of the office, and go talk to customers if we were going to have any hope at launching a viable business. So that’s exactly what we did.

Customer Discovery

Mechanical metamaterial engineering uses geometry to create lighter, stronger, and safer materials. The benefits of advanced materials are clearly valuable, but for who? And for what purpose?

If a lighter airplane can be safely made and flown, but it takes 15 years and tens of millions of dollars to be flight-certified, is it worth our time to try and sell our tech to an airplane manufacturer? Probably not.

If a mechanical metamaterial can couple linear and rotational motion to function like a mechanical hand, should we try to sell grippers to a robot company? Seems like a difficult business model.

What if we could make a more comfortable prosthetic liner for amputees? Do we dive headfirst into medical device regulation and health insurance reimbursement codes? Sounds like a challenge.

Using customer discovery to make better metamaterials

Truth is, these examples aren’t picked out of thin air – they’re all possibilities we considered, explored, and ruled out through an entrepreneurial method NSF exposed us to called customer discovery. Internally, we think of it as a “scientific method, but for building a business model.”

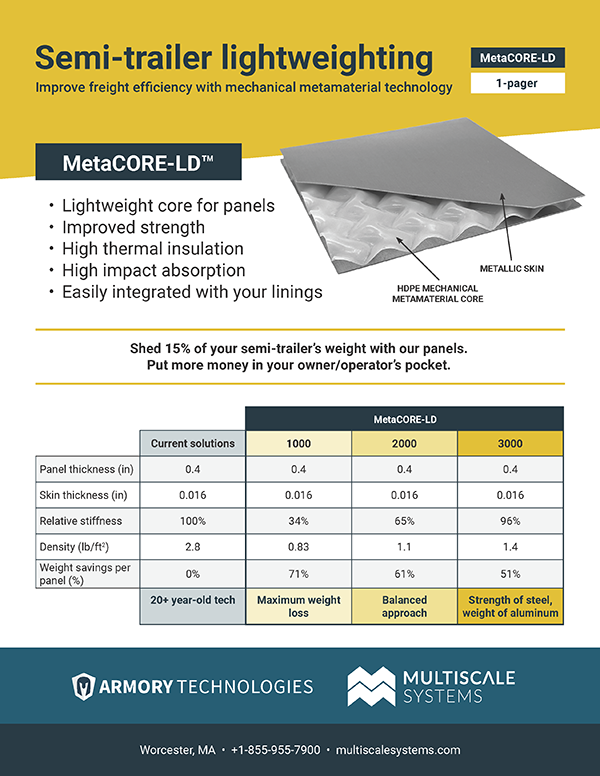

Basically, you form a hypothesis like “we can sell mechanical metamaterials to make lighter commercial semi-trailers.”

Then you find and listen to people who make, sell, own, and operate commercial semi-trailers.

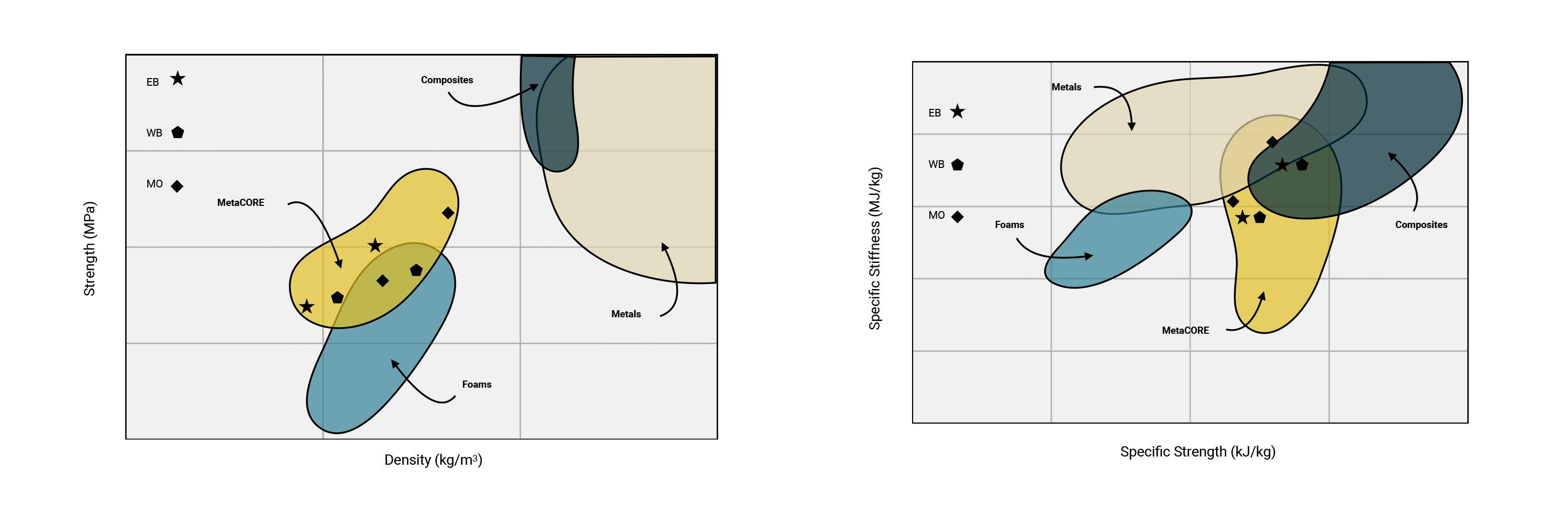

Left: A typical stress/strain curve for MetaCORE materials compared to foams, metals, and composites. Right: Ashby chart comparing strength and density of typical materials used in our target markets.

The importance of listening

An important lesson we learned early on during these customer discovery “interviews” is to keep our mouths shut, and let the other person do the talking. Pretty quickly, customer discovery revealed what people actually need (vs. what they want), whether they like the current solutions (or not), and what they’re actually willing to pay.

With enough customer discovery interviews, patterns emerge, and the initial hypothesis about lighter commercial tractor trailers can be tested against real-world data. This process quickly ruled out our initial hypotheses for how to go to market with our mechanical metamaterial technology – but it also surfaced new ideas we would never have considered.

Drilling down into market needs

After nearly 9 months of customer discovery, we were dialing in on a value proposition: materials that reduce weight without sacrificing strength for semi-trailer manufacturing. We sized the market, saw the commercial potential, but learned there were two immediate challenges to overcome.

First, it wasn’t good enough to just sell mechanical metamaterials. As with all new materials, they have to be used in a product relevant for semi-trailer manufacturing. But what product?

Second, a series of non-metamaterial questions popped up, like how our hypothetical product could be repaired, sourced, and integrated into a semi-trailer. At the early stages of building our business, we were still learning about our customers and hearing about these important questions for the first time.

Seed funding assists technology development

Because the NSF was providing a small (but stable) amount of seed funding, we worked hard to make every penny count. Our initial technology proposal evolved. We went from a vague sense of commercial potential to MetaCORE as a lightweight structural material, to eventually land on MetaCORE-LD, a sandwich panel product that leverages metamaterial properties to achieve meaningful weight reduction without sacrificing the semi-trailer’s strength or safety.

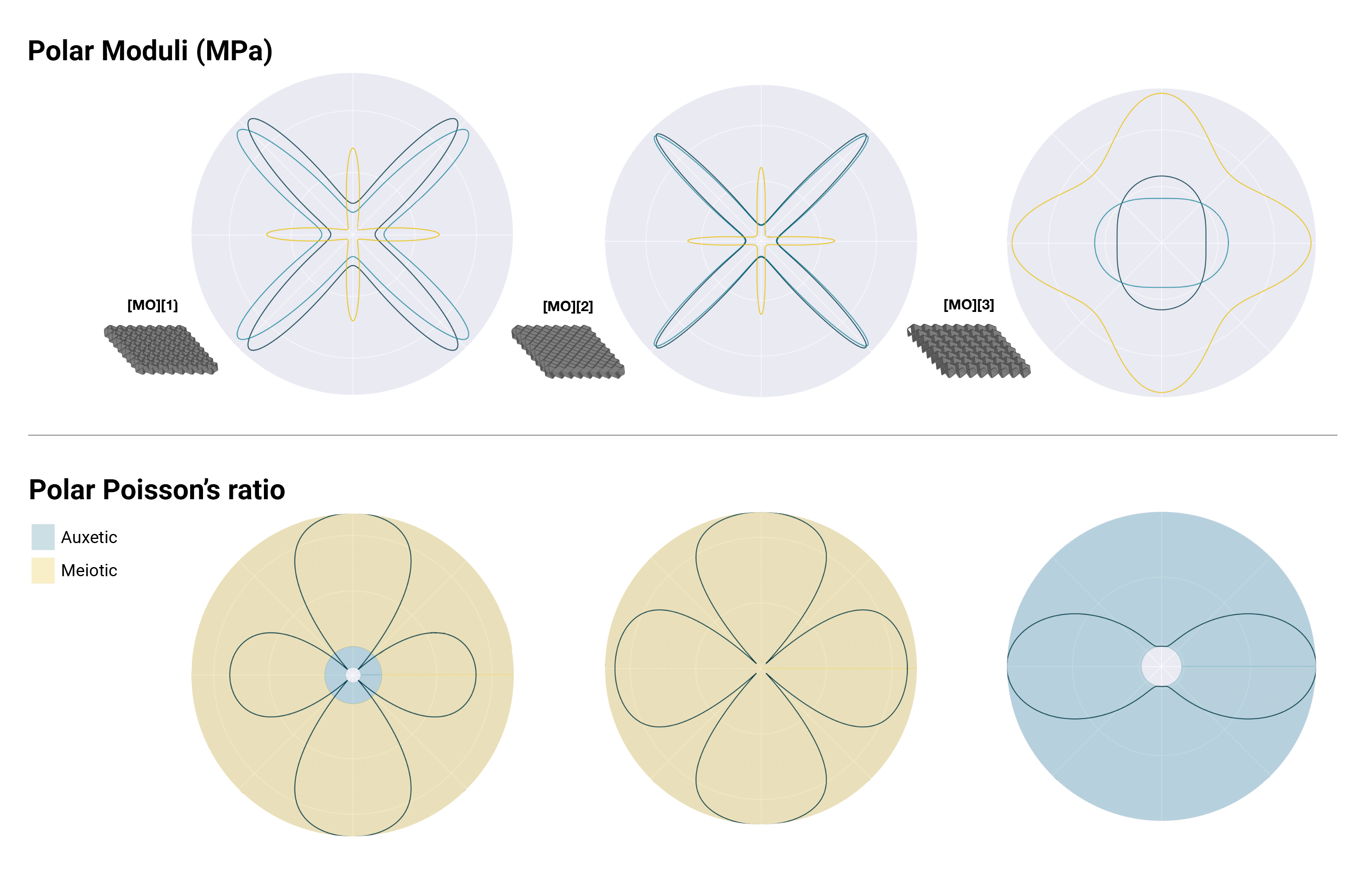

Top: MetaCORE [MO] polar plots of the three relevant in-plane elastic moduli. Bottom: Polar plots of Poisson’s Ratio.

Focusing technical effort on customer pain points

The NSF taught us that urgency for a solution and dissatisfaction with available choices are the guiding stars for navigating technology development. Focusing our technical effort accordingly led to several innovations as well as a newfound appreciation for the unique challenges in manufacturing, supply chain management, and quality control.

Lightweight structural panels like MetaCORE-LD have the potential to be a $1 billion opportunity across transportation, construction, and related industries. Customer discovery directly resulted in the ability to rely on existing contract manufacturing capacity distributed across the country.

Focusing specifically on semi-trailers, we’ve identified a pathway for substantial weight reduction, lowering total cost of ownership for fleet operators, and reducing greenhouse gas emissions as commercial transportation makes the transition from combustion engines to electric vehicles.

Outcomes and deliverables

With the NSF funding, we were able to launch the business with two full-time staff and generate critical technical data that led to a new patent for MetaCORE and associated trademarks.

Explore our technology development case studies

Department of Defense

Lessons learned from xTechSearch and technology development within the US Army.

NASA

Developing lightweight crash mitigation technology in preparation for the emerging UAMV market.

Department of Energy

A reliable replacement for elastomers used in high-temperature, high-pressure sealing applications

National Institute of Standards and Technology

Non-destructive testing of complex 3D geometry with optical metrology opens the door to high-quality mass production.