Creating Advanced Material Solutions

We love solving complex, technical problems. It’s a habit formed by years of academic research and built upon by contracts with numerous federal and private organizations. Today, we develop solutions for industries including aerospace, energy, and defense.

Our interdisciplinary team of physicists, engineers, and builders achieves success through creative ideation and intense technical validation.

We leverage our expertise in metamaterial composites to design material solutions that not only solve important problems, but do so by providing unique advanced functionality.

Technology Development

Federal Contracts & Awards

Partners & Accelerators

- Ansys

- Dawnbreaker

- FedTech

- Larta Institute

- Lever

- MassChallenge

- Massachusetts Clean Energy Center

- StartUp Worcester

- Massachusetts Manufacturing Innovation Initiative (M2I2)

- Venture Forum

Metamaterial Composites

More than the sum of their molecules

Multiscale Systems is the expert in metamaterial composites, a structural material that unlocks advanced functionality that’s difficult or impossible to create with normal materials.

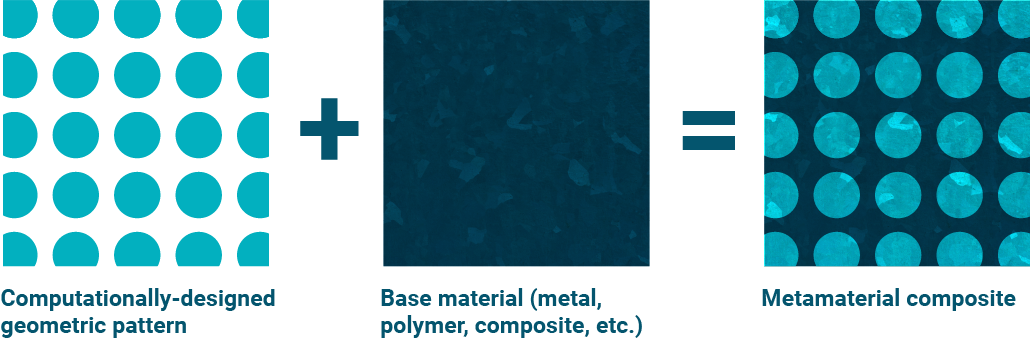

Metamaterials are common materials – like metals, polymers, and composites – formed into computationally generated, complex geometries. These geometries are tailored to each application, designed to provide enhanced performance and unique functionality.

Inspired by origami’s process of folding flat sheets into three-dimensional forms, metamaterial composites can be made using familiar manufacturing methods, such as additive manufacturing, thermoforming, and pattern transfer. Advanced functionality manifests through the unique combination of selected materials and patented geometric patterns.