Research

Creativity, collaboration, and ingenuity are at the heart of our research.

Creativity, collaboration, and ingenuity are at the heart of our research.

Inventing advanced material solutions

We love solving complex, technical problems. It’s a habit formed by years of academic research and built upon by contracts with numerous federal and private organizations. Today, we develop solutions for industries including aerospace, energy, and defense.

Our interdisciplinary team of physicists, engineers, and builders achieves success through creative ideation and intense technical validation.

We leverage our expertise in metamaterial composites to design material solutions that not only solve important problems, but do so by providing unique advanced functionality.

Technology development

Our technology has been developed under contract with several federal and private organizations.

Federal Contracts & Awards

Thermoplastic Composite Heliostat Structures

Prize Finalist 2024 Department of Energy Learn More

Bimetallic Functionally Graded Materials for High-Temperature Corrosion Resistance

SBIR Phase I 2023 Department of Energy Learn More

Hydrogen Transportation and Storage Components Made with Metal Hybrid Additive and Subtractive Manufacturing

SBIR Phase I 2023 Department of Energy Learn More

Wire-Laser Metal 3D Printed Bearings for Extreme Environments

SBIR Phase I 2023 NASA Learn More

Metal Additive Manufacturing of Functionally Graded Materials for Roller Bearings in High Temperature Sodium Systems

SBIR Phase I 2022 Department of Energy Learn More

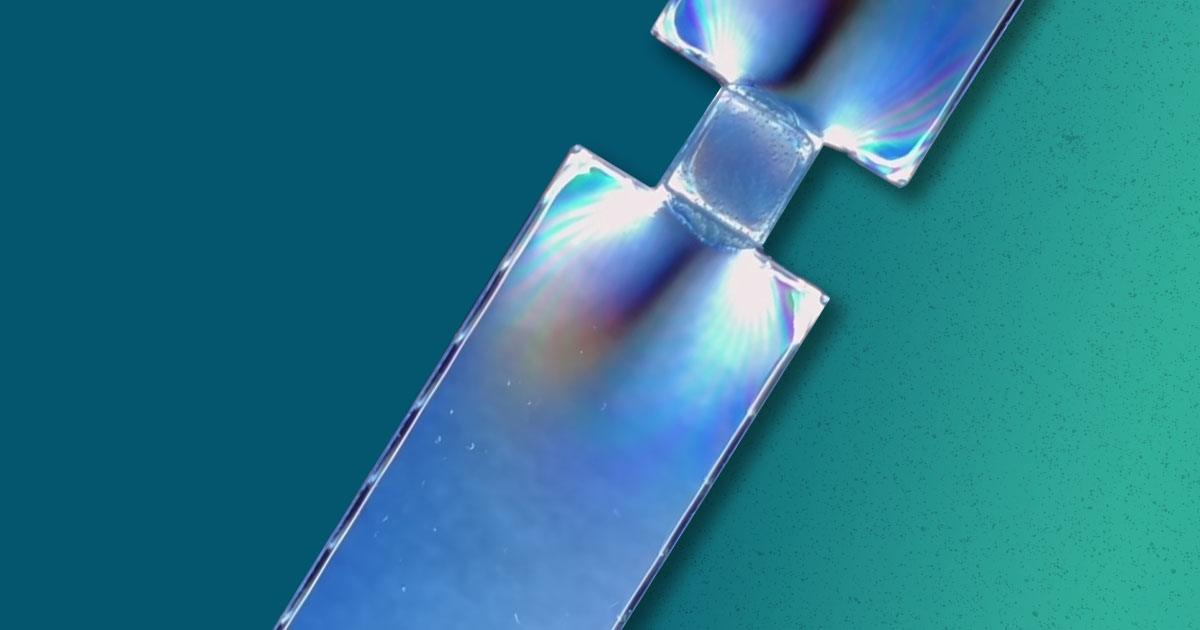

Contact-Free Metrology for Testing Metamaterial Quality

SBIR Phase II 2022 NIST Department of Commerce Learn More

Accelerated Aging of Lightweight High-Strength Mechanical Metamaterials

SBIR Phase I 2021 NASA Learn More

Additively Manufactured High-Strength Casing Connectors

Prize Semifinalist 2021 Department of Energy Learn More

Development and Application of Mechanical Metamaterials to Address Needs in Geothermal Technologies

SBIR Phase I 2020 Department of Energy

Ultra-Lightweight Mechanical Metamaterials for Mitigating Impacts and Crashes of Urban Air Mobility Vehicles

SBIR Phase II 2020 NASA Learn More

Lowering Hydro Costs with Mechanical Metamaterials

Prize Winner 2021 Department of Energy Learn More

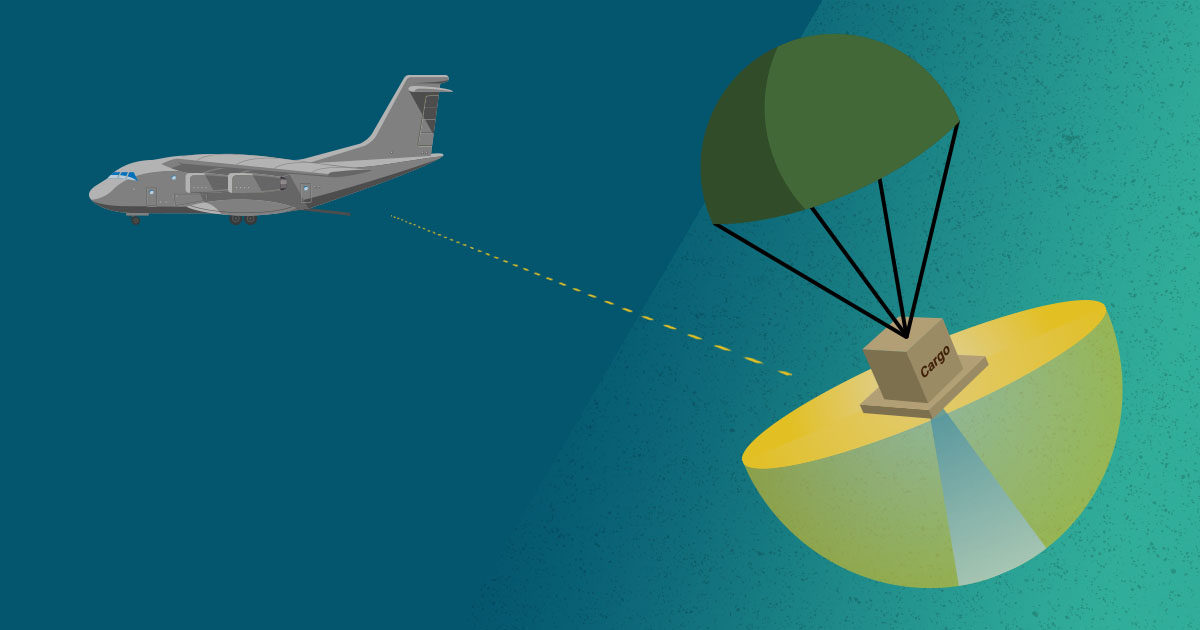

Lightweight, Impact Absorbing JPADS for Air Drops

Prize 2020 xTechSearch Learn More

Ultra Low-Cost Mechanical Metamaterials to Enable Mobility and Interactivity for Cyber-Physical Devices

SBIR Phase I 2019 National Science Foundation Learn More

Partners and Accelerators

Our partners provide invaluable support and resources:

- Ansys

- Dawnbreaker

- FedTech

- Larta Institute

- Lever

- MassChallenge

- Massachusetts Clean Energy Center

- StartUp Worcester

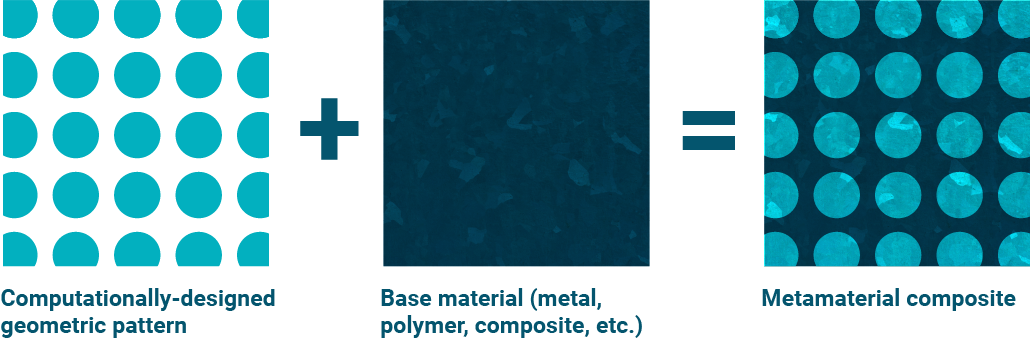

Metamaterial composites

More than the sum of their molecules

Multiscale Systems is the expert in metamaterial composites, a structural material that unlocks advanced functionality that’s difficult or impossible to create with normal materials.

Metamaterials are common materials – like metals, polymers, and composites – formed into computationally generated, complex geometries. These geometries are tailored to each application, designed to provide enhanced performance and unique functionality.

Inspired by origami’s process of folding flat sheets into three-dimensional forms, metamaterial composites can be made using familiar manufacturing methods, such as additive manufacturing, thermoforming, and pattern transfer. Advanced functionality manifests through the unique combination of selected materials and patented geometric patterns.

Metamaterial composite technologies

Created under contract with NASA and the U.S. Department of Energy, these technologies have been designed with specific application functionality.

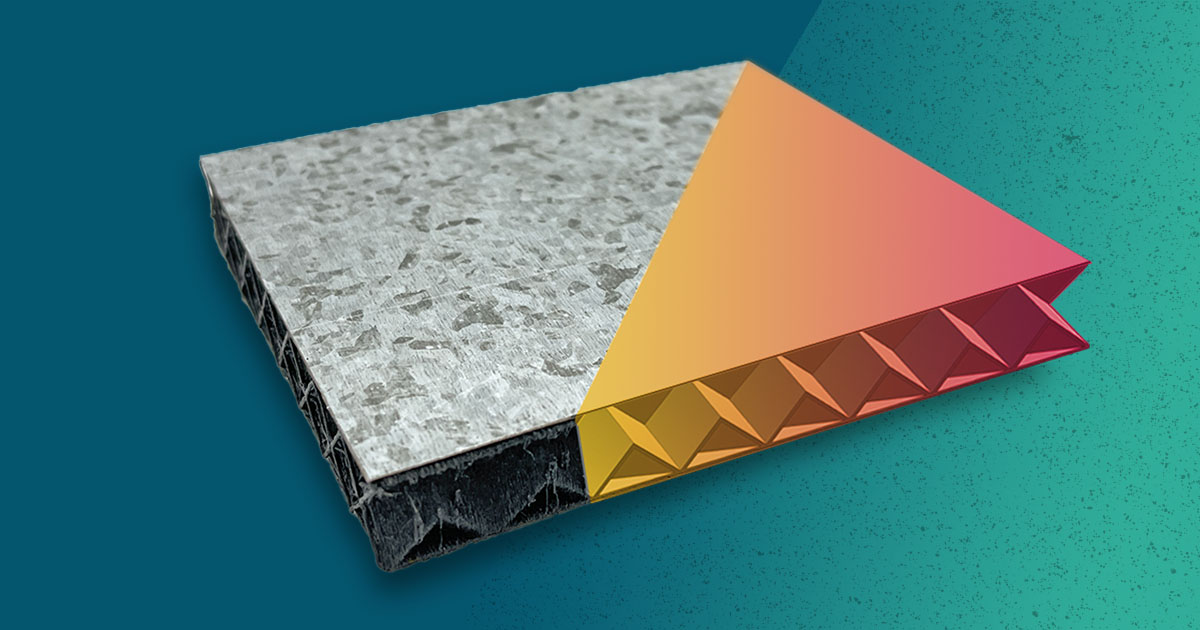

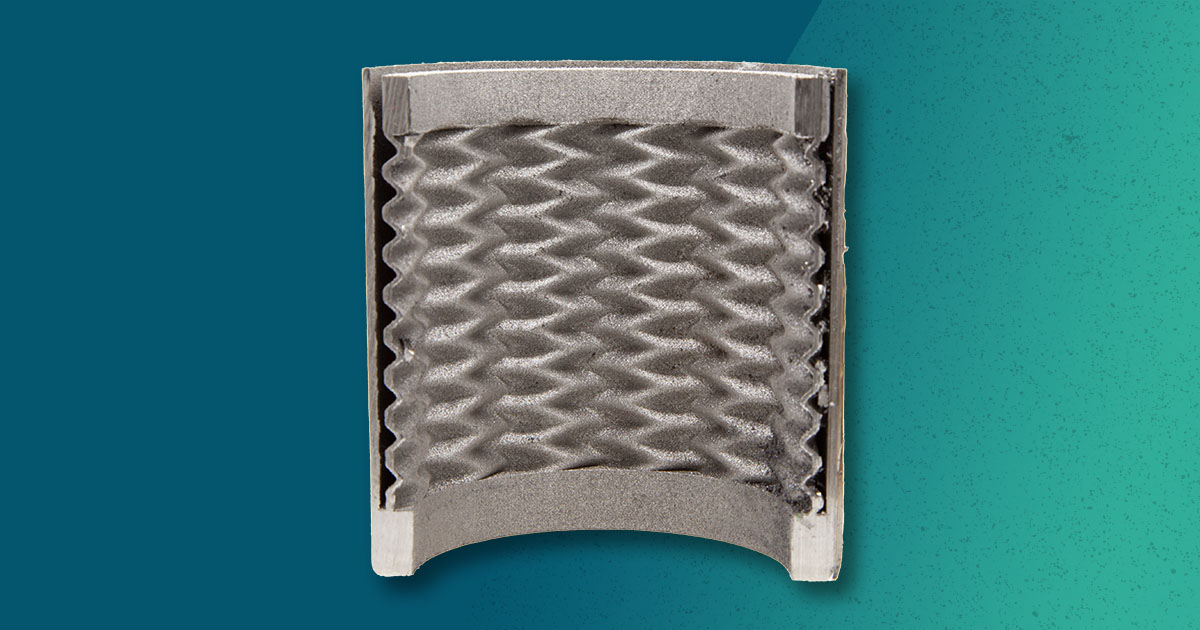

MetaCORE®

Ideal energy absorber

Isotropic energy absorption

Lightweight

Mitigates sudden deceleration

Customizable crush strength

MetaCORE®-LD

Lightweight sandwich panel

Low density cores

High shear strength

Temperature regulation

Sustainable materials

MetaTHERM®

Extreme environment survivability

Holds severe pressure differentials

Controls thermal expansion

Regulates temperature

Mitigates equipment failure

Technology development case studies

Dive deeper into our R&D through case studies. We examine lessons learned and insights gained while developing our technology.

In 2019, we won an NSF SBIR for development of mechanical metamaterials. What began as a general desire to do something with our metamaterial research evolved into a targeted commercialization strategy for MetaCORE-LD as an alternative lightweight sandwich panel for semi-trailers.

Safety is a big concern for UAMVs. NASA is proactively seeding the development of lightweight crash mitigation technology in preparation for this emerging mode of transportation.

The U.S. Army is modernizing its acquisition of disruptive technologies like our mechanical metamaterial solutions. Representatives from AFC and ASA(ALT) selected Multiscale Systems’ MetaCORE technology for acceleration through the xTechSearch program.

Achieving utility scale geothermal energy is bottlenecked by the cost of equipment failure in extreme downhole environments. New materials – like MetaTHERM – are required to unlock the potential of Enhanced Geothermal Systems (EGS).

In 2021, we received an SBIR contract from the National Institute of Standards and Technology (NIST) for the development of a contact-free optical metrology method to standardize the manufacturing of mechanical metamaterials.